Check out more coverage of APEC 2024.

According to Texas Instruments, its latest high-density isolated DC-DC modules with integrated transformers shrink isolated bias power supplies in automotive and industrial systems by close to 90%.

The purpose of any isolated bias power supply is to deliver power to the analog and digital control ICs in a system. In general, such isolated power supplies come in the form of flyback and push-pull converters, which use heavy and bulky transformers to grant galvanic isolation between the input and any outputs. But these magnetic components are vulnerable to vibrations and other harsh conditions that are present on factory floors and under the hood of cars, inducing electromagnetic interference (EMI) that can impact the system’s performance.

The UCC33420 uses TI's next-gen integrated transformer technology to remove the usual requirement for a separate transformer in the isolated bias power supply. A high-efficiency DC-DC converter is placed in the same package as a planar transformer that’s manufactured on a silicon chip without using traditional metal windings. That gives you the ability to reduce the footprint of the power supply to a large degree, while reducing the bill of materials (BOM) by about 50%, said the company.

DC-DC Module Details

The DC-DC module integrates the isolated power transformer, primary- and secondary-side bridges, and control logic in a single package, pushing the limits of power density in automotive- and industrial-grade systems. On top of being very compact, the chips have tight output-voltage regulation and high density, as they can safely deliver 1.5 W of output power to several analog and digital controllers at once, said TI.

Touting 3X higher power density than other modules on the market, according to TI, the isolated DC-DC module delivers the highest output power and most robust isolation for automotive- and industrial-grade systems in a 4- × 5-mm very thin small outline no-lead (VSON) package that’s a mere 1 mm tall. The power module was on display at the Applied Power Electronics Conference (APEC) last month.

By tapping into TI’s integrated transformer technology, the DC-DC module provides galvanic isolation to prevent the undesirable flow of DC or AC current between different components while allowing for the safe transfer of signals and power with high reliability. The module is rated for up to 3 kV RMS of electronic isolation, and it can support up to 200 V/ns of common-mode transient immunity (CMTI).

TI said the integrated transformer is also designed to reduce EMI, giving you the ability to reduce the complexity of the EMI filters or the flexibility to remove them entirely.

The isolated bias supply can pump out 3.3 and 5 V with ±3% accuracy, and input voltages of 3 to 3.6 V and 4.5 to 5.5V, without requiring the use of LDOs or other regulator ICs to adjust the voltage.

Taking on the EV BMS

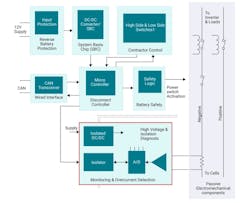

TI said the automotive-grade UCC33420-Q1 is a fit for electric-vehicle (EV) battery-management systems (BMS), which is responsible for monitoring the voltage and current of the battery cells and pack that contains them. Monitoring the leakage current and isolation resistance between the bus and the chassis ground in high-voltage battery packs is vitally important to meet safety standards, stated TI.

The isolated DC-DC power supply can be used in the high-voltage diagnosis subsystem within the BMS, as it delivers isolated power to digital isolators and current or voltage sensors. The safety power-management IC sends 5 V to the input of the isolated bias power supply and then pumps out 5 V of output power to all components placed on the high-voltage side of the EV battery disconnect unit (BDU).

In an intelligent battery junction box using a single voltage, current, and insulation resistance monitor, the isolated DC-DC power supply outputs 5 V of power to the battery monitor. TI said that its integrated transformer technology saves space on the circuit board compared with a standard DC-DC converter topology, which maximizes power density and minimizes costs by reducing the BOM of the system.

The same qualities that lend themselves to EVs are also relevant for supplying isolated DC-DC power to offboard EV chargers and high-end programmable logic controller (PLC) modules in factories, said TI.

The company further noted that the DC-DC modules also excel in space-constrained power-delivery systems in data centers. AI is driving power demands up to 90 kW per server rack, considerably more than the 15 to 30 kW at present.