Many forces are driving our society to improve the electrical grid, and manufacturers of regular power transformers are aiming their efforts with products to meet the needs of a rapidly growing smart-grid infrastructure. Serving this impetus is the tremendous increase in interactive digital communications, stricter government environmental, reliability and efficiency regulations, the adoption of smart metering, and a greater reliance on secondary side power.

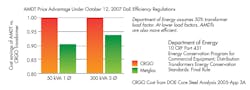

This is particularly true on the distribution side of electric power, where the total cost of ownership and payback for a utility and the end user over the useful life of a transformer is taken into consideration. According to Metglas Inc., a fully owned subsidiary of Hitachi America Metals Ltd., amorphous metal power transformers are less costly and more efficient than cold-rolled grain-oriented steel transformers.

The company manufactures amorphous metal power transformers using a proprietary process. The key to Metglas’ rapid-solidification manufacturing process is cooling the molten alloy at a rate of approximately 1 million ºC/s, using a melt spinning technique.

In this melt-spinning process from Metglas, amorphous foil is made for power transformers using rapid solidification at a rate of one million ºC/s. (Source: Metglas)

Metglas says hundreds of utilities are benefiting from amorphous-metal core transformers. By replacing conventional distribution transformers with amorphous-metal types, approximately 27 TWh of core losses in the U.S. alone could result in annual savings.

In an amorphous metal transformer, the magnetic core is made with a ferromagnetic amorphous metal alloy. Typical alloy material consists of iron with boron, silicon, and phosphorus in the form of thin (e.g., 25 µm) foils. These materials have high magnetic susceptibility, very low coercivity, and high electrical resistance. The high resistance and thin foils lead to low losses by eddy currents when subjected to alternating magnetic fields.

On the other hand, Metglas alloys have a lower saturation induction and often a higher magneto-striction compared to conventional crystalline iron-silicon electrical steel. This causes energy loss due to frictional heating in susceptible ferromagnetic cores. It is also responsible for the low-pitched humming sound that can be heard coming from transformers.

Running cool for lower energy costs can be achieved using amorphous metal distribution transformers (AMDTs) like those made by Metglas, compared with transformers made of cold-rolled grain-oriented (CRGO) steel. (Source: Metaglas)

Amorphous core technology is also used by the United Kingdom’s Wilson Power Solutions, which is upgrading its products for the smart grid. Its e2+ transformers come with a 17-position on-load tap changer that adjusts the taps automatically to maintain a constant secondary output voltage (relative to input voltage fluctuations). This is done via a volt-ampere reactive relay, where site supply voltages fluctuate, or a constant ±1% output voltage is required.

An area of interest Wilson is investigating is the ideal temperature and drying conditions in the manufacture of a power transformer. It is trying to come up a reasonable temperature of say 65°C to 75°C. A constant temperature says Wilson allows fans to turn on sooner, which could keep the core of the transformer cooler and thus increase efficiency.

Despite the fact that most power transformers are not quite yet ready for the emerging smart grid, there’s room for improvement for incorporating remote diagnostic smart monitoring of a wide range of transformer and system parameters, claims Mike Dickinson, director of new business development at Pacific Crest Transformers. The company is building next-generation transformers for integration into the smart grid infrastructure.

Dickinson sees transformers used in power transmission as immediate candidates for integration in the smart grid, with resulting immediate benefits of enhanced energy security, reduced greenhouse gas emissions, improved urban air quality and greater grid utilization. Vital power transformer statistics like temperature, pressure, liquid and vacuum levels, water content in oil, the percentage of hydrogen gas present. System parameters like cooling fan status, loss of power, ambient temperature, input and output voltages, and output current, can be collected and monitored in real time by a central clearinghouse.

Improvements in power transformers will address the needs of the smart grid. Benefits include enhanced energy security, reduced greenhouse gas emissions, improved urban air quality, and greater grid utilization.

Dickinson cites a growing interest in conducting dissolved gas analysis of the oil in a transformer by taking samples of the transformer’s oil gases. This allows one to determine if any events occurred that might be detrimental to a transformer that could reduce its life.

Energy performance legislation for distribution transformers is being promoted globally by the European Committee for Electrotechnical Standardization (CENELEC). The committee two years ago issued a minimum energy performance standard (MEPS) spelling out maximum losses for a distribution transformer’s core and winding, and minimum peak efficiency for power transformers. The Tier 2 MEPS standard is due to be implemented in 2021.

This will require the use of higher-quality grades of steel, changes to the transformer’s design, better and tighter windings, and improved manufacturing methods to reduce coil losses, points out Ales Bertuzzi. He is the leader of the European transformer manufacturer alliance Trafogrid and managing director at Italy’s power transformer manufacturer L. A. E. LLC. “The use of higher-quality electric steel, flat-core designs, oval-wrapped low-voltage copper coils, and implementing the right tensioning in low- and high-voltage coils can be helpful in reaching the Tier 2 MEPS standard,” he says.

Beyond improvements in present-day transformer size, weight, reliability, and efficiency attributes, solid-state power transformers may play a leading role in the secondary side of the smart power grid. But that remains to be seen since much solid-state work is in the R&D and prototyping phase with simulation models being developed.