LEDs have proliferated through countless applications and across all markets over the course of this decade (Fig. 1). As the LED market has reached economies of scale, applications once dominated by traditional incandescent lighting are now utilizing many key features of LED technology—high efficiency, high brightness, precise control of light, vast arrays of colors, unique shapes in conjunction with new optics, and more. LED illumination rise time is twice as fast as incandescent sources and consumes less power than its incandescent counterpart, leading to substantial advantages in energy consumption.

Improvements to LEDs and LED drivers allow for applications that weren’t traditionally possible and help in adapting them to new market needs. Industrial and stage lighting provides high-contrast, bright, and colorful systems for illuminating the stage. Horticulture lighting utilizes highly efficient designs at various color spectrums to effectively grow high-yielding plants. Machine-vision systems require sophisticated camera systems that employ infrared or high-brightness LEDs (HB LEDs). IoT lighting creates smart and well-lit applications that bring comfort and simplicity to its users.

These represent only a few applications that require an LED paired with an LED driver. LED drivers, the electronics behind LED operation, play an important part in preserving and enhancing the inherent LED qualities of clarity, speed, and efficiency.

Powering the LEDs

LEDs are used in many general lighting applications and are available in diverse configurations ranging from a single LED to a string or matrix of LEDs. HB LEDs require constant current for optimal performance. The current correlates with junction temperature and, therefore, color. Accordingly, HB LEDs must be driven with current, not voltage. The LED power source ranges from an ac-dc power adapter for building illumination to a few AAA batteries for closet lights and other household devices.

The Challenges

The proliferation of LED modules in general lighting places new requirements on system hardware, including reduced EMI, reduced component size to fit additional electronics within the same space, improved energy efficiency to perform within the same or lower thermal budget, supporting connected and flexible architectures that enable multiple configurations, as well as accurate control to preserve LED light characteristics. This article will cover the following applications: high-power LED lighting, low/mid-power LED lighting, infrared (IR) diodes for vision systems, and low-power LED lighting.

High-Power LED Lighting

Buck-Boost Average Current Control

In line-operated applications, a switched string of diodes can be fully engaged with 12 LED diodes (42 V) or dimmed down to a single LED diode (3.5 V). The LED driver may have an input voltage of 24 V, while its output voltage may go from 3.5 to 42 V and be above or below the input at any given time.

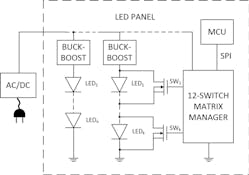

Typical LED panels take power from a separate ac-dc power-supply brick. The power brick delivers a standard dc voltage, for example 24 V. Dedicated buck-boost converters, working from this power brick input, control the lamp’s intensity and position. Each buck-boost converter controls a single function, such as daytime or nighttime lights, light position, etc. The matrix manager switches the string diodes in or out, with each buck converter’s output adjusted accordingly.

Ideally, each string will have a customized buck-boost solution, where the string voltage is directly derived from the power brick, with a step-down conversion when possible (buck mode) and a step-up conversion when necessary. Having as low an input voltage as possible reduces system switching losses and improves efficiency.

Another concern is current and voltage accuracy. The typical peak or valley current-mode buck converter controls the inductor peak current. However, the diode string current is the average current in the inductor. This peak-to-average current error is eventually eliminated by the outer voltage control loop, but returns during transient conditions.

For example, in Figure 2, the matrix manager may instantly raise the number of powered-up diodes from 8 to 12. The resulting output-voltage step produces a current and voltage fluctuation at the output of the buck converter that takes tens of microseconds to extinguish. A high-ratio PWM dimming circuit will sample this current for only a few initial microseconds where the amplitude is dipping, resulting in incorrect dimming brightness and color. A control loop that measures average current, as opposed to peak current, would naturally eliminate this problem.

Dimming is a ubiquitous function in many applications and an important safety feature for LED headlights. The human eye can barely detect light dimming from 100% to 50%. Dimming must go down to 1% or less to be clearly discernible. With this in mind, it’s not surprising that dimming is specified by a ratio of 1000:1 or higher. Given that the human eye, under proper conditions, can sense a single photon, there’s practically no limit to this function.

Since current must be kept constant to preserve color, the best dimming strategy for LEDs is pulse-width modulation (PWM), where the light intensity is modulated by time-slicing the current rather than by changing the amplitude. The PWM frequency must be kept above 200 Hz to prevent the human eye from perceiving the LED light as flickering.

With PWM dimming, the limit to the minimum LED “on/off” time is the time it takes to ramp up/down the current in the switching regulator inductor. This may add up to tens of microseconds of response time, which is too slow for applications that require fast, complex dimming patterns. Dimming in this case can only be performed by individually shunting each LED in a string by means of dedicated MOSFET switches (SW1-K in Fig. 2). The challenge for the current control loop is to be fast enough to quickly recover from the output-voltage transient due to switching in and out of the diodes.

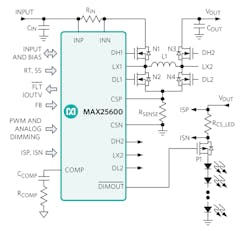

An ideal solution should meet the requirements of smooth buck-boost operation and fast transient response. The LED controller shown in Figure 3 enables such a solution.

Typically, the diode string is attached directly to VOUT. The IC integrates a high-side p-channel dimming MOSFET driver (/DIMOUT\) for applications that require a current source with PWM dimming capability as shown in Figure 3.

High-Power Buck LED Controller

Buck converters (a.k.a. direct energy devices), thanks to their uninterrupted current flow from the inductor to the output, are inherently more efficient than boost and buck-boost converters. Naturally, the use of a buck converter implies that the output voltage is always lower than the input voltage. Whenever possible, based on the characteristics of the application, buck converters result in more efficient lighting fixtures.

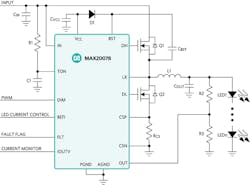

An ideal solution should meet the requirements of a wide input voltage range, fast transient response, and high and well-controlled switching frequency, all while enabling high efficiency with synchronous rectification. The LED controller in Figure 4 enables such a solution.

Dual LED Buck Controllers

The space challenge clearly points to more integration of the LED controller building blocks, while the reconfiguration for fast time-to-market points to an ability to communicate with the LED controller IC.

The synchronous, all n-channel buck LED controller with SPI interface (Fig. 5) integrates two channels in a single IC, which reduces the BOM and solution footprint. Two out-of-phase channels smooth out the input current, spreading out its energy, resulting in lower RMS current and lower EMI emissions. With a lower RMS current, smaller and less expensive input capacitors can be used. A high, well-controlled switching frequency, outside the AM frequency band, reduces radio-frequency interference and meets EMI standards. Fast transient response prevents output voltage and current fluctuations, which is consequent to instantaneous variation of the diode string length in high-ratio dimming applications. The device is ideal for matrix lighting and LED-driver module (LDM) platforms.

Utilizing an advanced silicon process allows the entire dual-controller function to be housed in a small package. Synchronous rectification eliminates Schottky diodes and greatly reduces power losses in high-current applications, while enabling the use of smaller discrete MOSFETs.

Low-/Mid-Power Lighting

Flexible LED Drivers

LEDs have penetrated many lighting applications thanks to their versatility and efficiency. As an example, portable LED applications must be small and efficient enough to fit in the existing space without overheating. With so many different functions, one might expect a lighting manufacturer to be resigned to keeping a large quantity of different LED drivers in stock. This can have severe implications in terms of reducing a manufacturer’s purchasing power due to low volume orders, longer design cycles, and delayed time to market.

Is it possible to have an efficient, highly integrated LED driver that’s flexible enough to cover the majority of applications? This case study reviews the power requirements of three classes of LED lighting applications and highlights the optimal LED-driver topology for each case (buck, boost, buck-boost). It then introduces an innovative buck-derived solution that meets integration, efficiency, and flexibility challenges.

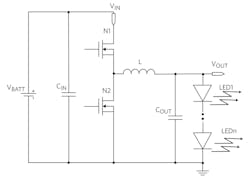

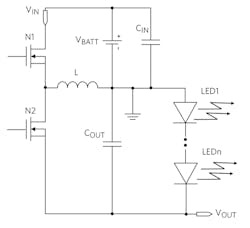

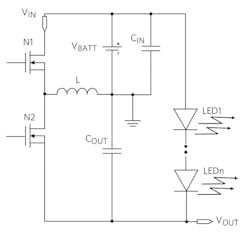

Closet lights, shed lights, and other home applications require one or two LED diodes for operation and are often battery-operated. For a typical LED diode that develops 3.5 V at 1 A, this type of application can be well-served by a simple buck converter powered by a 9-V battery. In Figure 6, the buck-converter inductor current builds up when N1 is “on” and is maintained “on” through N2 when N1 is “off.” Synchronous rectification accounts for the high efficiency.

Brighter home applications may require three or four LED lights to operate. Here, the voltage ranges from 10.5 to 14 V. With our 9-V battery, the best configuration for this type of application is a buck-boost converter.

One example of a buck-derived buck-boost implementation is shown in Figure 7. Notice how the output voltage is always below ground. The inductor builds up current when N1 is “on” and is maintained through N2 when N1 is “off.” The voltage across the inductor inverts at each transition, independently of the number of diodes. Accordingly, this configuration can operate with any number of diodes on the output, and a string voltage drop that adds up to a value that’s above or below the input voltage (buck-boost operation).

The brightest applications may require long strings of diodes. In this case, the best configuration is the boost converter. In a buck-derived boost converter (Fig. 8), the output voltage floats below the input voltage. The inductor builds up current when N1 is “on” and is mantained through N2 when N1 is “off.” For the voltage across the inductor to invert at each transition, the number of diodes must be high enough so that the output voltage is negative with respect to ground. For this reason, the configuration can only operate with a high number of diodes in the string, which in this case is eight (28-V string).

Buck, boost, and buck-boost canonical implementations can be very different and are very difficult to reconcile in a single IC. However, in portable LED applications, it makes no difference where the string is voltage-referenced. This opens up the opportunity to adopt a buck-derived topology for both the buck-boost and boost converter.

In the above three examples, the cathode of the LED’s bottom diode is opportunistically referenced to ground (buck) or VOUT (buck-boost and boost), while the anode of the LED’s top diode is referenced to VOUT (buck) or ground (buck-boost and boost). Indeed, it’s possible in this application to have a single flexible topology for all cases, with minor adjustments of the IC and the application configuration.

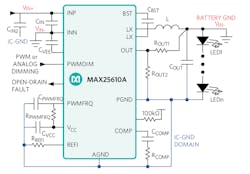

The IC in Figure 9 is a fully synchronous LED driver that provides constant output current to drive high-power LEDs. The IC integrates two 60-mΩ power MOSFETs for synchronous operation, high efficiency, and a minimum number of external components. Flexible configuration supports buck, inverting buck-boost, and boost conversion. The devices can operate in two modes. For buck mode, connect a 2.49-kΩ resistor from VCC to the PWMFRQ pin. For buck-boost or boost mode, connect a 17.8-kΩ resistor from VCC to the PWMFRQ pin.

Infrared Diode for Vision Systems

Machine vision is an important tool for Industry 4.0. Infrared (IR) cameras utilize an IR LED in combination with a photo sensor and are critical components of machine vision, which is used to measure and count products, calculate product weight or volume, and inspect goods at top speed with respect to predefined characteristics. IR machine-vision lighting enables industrial vision systems to recognize objects and their condition under difficult lighting conditions such as reflective surfaces that produce high levels of visible-spectrum noise, high or low levels of illumination, or target areas with variable light intensities.

All of these functions and their associated electronics must fit seamlessly inside a robot, creating the need for flexible, small, and efficient solutions. They must also cope with harsh industrial electrical environments.

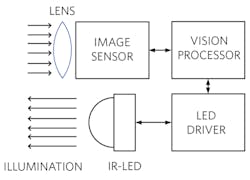

Some key advantages of IR light are its invisibility to the human eye and its ability to work day and night. Figure 10 shows the main elements of an infrared camera. The IR LED illuminates the target. The reflected light is collected by the image sensor (CCD or CMOS photodiode) and processed by the vision processor to determine the response to the situation at hand.

The LED driver controls the IR light intensity and strobes it at the right frequency and duty cycle. Ideally, it must work off a low-voltage dc rail and cope with a harsh industrial environment.

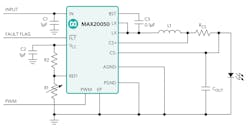

The industrial environment is subject to electromagnetic interference (EMI) due to both external and internal sources. The “arc and spark” noise that comes from soldering components, motors, and similar pulse-type systems affects the supply voltage rails by producing disruptive undervoltages or overvoltages. The IR LED buck converter, despite its fast switching waveforms, should mitigate any contribution to this noisy environment. As an example, the synchronous buck LED driver in Figure 11 offers a solution.

Low-Power LED Lighting

Small Lights

Low-power applications can be powered by the ac-line or by batteries. In battery-operated applications, like closet lighting and other household applications, the power source can be a few AAA batteries, with wide input voltage swings.

These home and building applications require less power and are handled by simple single-function ICs. Here, the MAX20090 can be utilized as a boost LED controller for long strings that require voltages above the nominal power brick or battery voltage, or as a front-end boost voltage regulator. The buck converter in Figure 11 can drive short strings of diodes that are connected to the battery or to a low-voltage power brick. Alternatively, it can drive long strings of diodes with the help of a front-end boost converter.

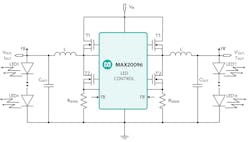

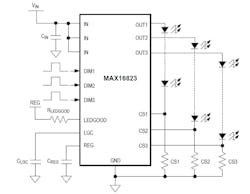

For noise-sensitive applications, a linear LED driver can be utilized. The three-channel LED driver in Figure 12 operates from a 5.5- to 40-V input voltage range and delivers up to 100 mA per channel to one or more strings of HB LEDs. Each channel’s current is programmable using an external current-sense resistor in series with the LEDs. Three DIM inputs allow for a wide range of independent pulsed dimming in addition to providing the on and off control of the outputs. Wave-shaping circuitry reduces EMI while providing fast turn-on and turn-off times.

Conclusion

The proliferation of LED modules in general lighting applications places new requirements on system hardware, including reduced component size to fit additional electronics in the same space, improved energy efficiency to perform within the same or lower thermal budget, connected and flexible architectures that support multiple configurations, and accurate control to preserve LED light characteristics.

This article discussed the challenges in high-power and low/mid-power lighting, IR cameras used in vision systems, and low-power lighting. In each case, the best solution, based on the application at hand, was proposed.

Yin Wu is an MBA and MSEE, and Nazzareno (Reno) Rossetti is an analog and mixed-signal expert at Maxim Integrated.

Related Resources