A pacemaker is a battery-operated device placed in body to produce electrical pulses that cause the heart to beat at a normal rate. Recent research studies have described the use of energy harvesting to power a pacemaker. The goal for energy harvesting in this case is to eliminate the need for a battery by generating electricity derived from an external source.

Eliminating the battery would get rid of the weakest link in the pacemaker’s reliability chain. Once a pacemaker battery reaches a critically low energy level, physicians must replace a correctly functioning pacemaker in a surgical intervention, which increases costs and adds possible patient complications. In addition, wires from the battery to the pacemaker are prone to fracture.

Related Articles

- Power Leap for Energy Harvesting

- Energy Harvesting Powers Wireless Sensor Networks In Industrial Apps

- Energy Harvesting Efforts Are Picking Up Steam

- Effective Energy-Harvesting Requires Appropriate Components

- Sensors/Transducers Double AS Power Sources

- Step-Up Converter/Power Manager Harvests Energy from ±30mV Inputs

Replacing batteries with an external energy source would spare patients from repeated interventions and make pacemaker wires obsolete. Researchers didn’t have to look far for a good source of energy. The heart is a promising external energy source for energy harvesting in the body because its contractions are repetitive and occur 24 hours a day, 7 days a week around the clock.

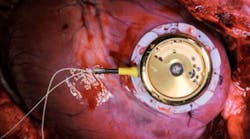

Drawing on their clock-making heritage, Swiss scientists from the University of Bern are adapting technology from automatic watches to power pacemakers with nothing more than the motion of the beating heart. The Swiss automatic wristwatch mechanism, invented in 1777, has a good reputation as a reliable technology.

Adrian Zurbuchen of the university of Bern explained that an automatic watch ‘harvests’ its energy from the wrist by transforming mechanical energy into electrical energy. An automatic wristwatch accelerates due to the movement of the wearer’s arm. This rotation progressively winds a mechanical spring that, once fully charged, unwinds again and spins an electrical micro-generator. Thus, attaching a pacemaker to the heart would allow a similar system to be directly exposed to the movement of the heart’s myocardial muscle.

Researchers copied the wristwatch mechanism. They removed unnecessary parts to reduce weight and size and then developed a custom-made housing with eyelets so it could be stitched directly onto the heart muscle tissue. Results showed that the device generated a mean output power of 52 microwatts, which is more than adequate to power a modern pacemaker that consumes only about 10 microwatts. It was implanted into a 60 kg pig where it successfully restored its heartbeat to 130 beats per minute.

To test the prototype, researchers developed an electronic circuit to transform and store the power into a small energy buffer and then sent it to a custom-made cardiac pacemaker. The system works in three steps. First, the harvesting prototype acquires energy from the heart. Then, the energy is temporarily stored in the energy buffer. Next, the buffered energy powers the pacemaker, which applies stimuli to the heart.

“This answers our core question that heart motion can be converted into electrical energy that exceeds power requirements of modern pacemakers,” said Zurbuchen, whose group now plans to reduce the size and weight of the prototype to make it more sensitive to heart motion. Zurbuchen added that the technology has potential for use in a multitude of devices, including defibrillators, loop recorders and drug delivery pumps.

University of Michigan

At the University of Michigan, scientists are working on another approach to a battery-free pacemaker. The American Heart Association revealed that researchers at the University of Michigan are developing a prototype piezoelectric energy-harvesting device that provides more than enough energy to power a pacemaker. Their research has led to fresh speculation that piezoelectricity, electricity converted from mechanical stresses undergone by a generator, may one day provide an alternative to battery-powered pacemakers.

News reports have suggested that the prototype has harvested energy directly from the human heart. Actually, the scientists measured simulated heartbeat-induced vibrations, similar to the actual heart vibrations. The used a shaker to reproduce the vibrations in the laboratory and connected it to a prototype cardiac energy harvester they developed. Measurements of the prototype's performance, based on sets of 100 simulated heartbeats at various heart rates, showed the energy harvester performed as the scientists had predicted – generating more than 10 times the power required for a modern pacemaker.

Research suggests that the prototype could draw sufficient energy from the heart at pulse rates of anywhere between 20 and 600 beats per minute. It's claimed that, unlike battery-powered pacemakers, the device is not affected by electromagnetic interference from devices such as mobile phones.

The distinction between a heart-powered prototype and a prototype made to run from equivalent power levels is an important one, and the American Heart Association statement describes implants as the next step, though the research to date is described as preliminary. The Heart Association provided no details of the prototype's inner workings; however, functionally-similar prototypes have been developed in the past. This is a reminder that progress almost always occurs in fractional increments.

Northwestern University

Using another piezoelectric approach, an interdisciplinary research team including Northwestern University’s Yonggang Huang developed a flexible medical implant that harvests the energy of the beating heart. Huang is the Joseph Cummings Professor of Civil and Environmental Engineering and Mechanical Engineering at Northwestern’s McCormick School of Engineering and Applied Science.

Huang and his longtime collaborator John A. Rogers of the University of Illinois worked with cardiologists at the University of Arizona. The interdisciplinary team developed and demonstrated a device that converts the mechanical energy from the natural motions of the heart, lung and diaphragm into electrical energy -- enough to easily charge a pacemaker or battery for other practical uses.

“Unlike our earlier stretchable electronics work, this time we wanted the strain in our piezoelectric material for the mechanical energy it produces, and our challenge was that we had to control that strain very precisely,” said Huang, who led the portion of the research focused on theory, design and modeling.

Piezoelectric devices produce a voltage when it they are pressed or bent. “We carefully designed the device so the piezoelectric material would be pushed to nearly the breaking point, where we could capture the maximum amount of energy,” Huang said. “Once this kind of energy is harvested, it can charge a lot of different implantable devices.”

“I think the concept of creating electrical power from motions in internal organs is really interesting,” Rogers said. “The key thing is, if you’re going to do this, you need to be able to achieve efficiency and ultimately power output that is of practical use.

Rogers led the group that worked on the experimental and fabrication work of the implantable device. He is the Swanlund Chair at the University of Illinois at Urbana-Champaign.

The piezoelectric material Huang and Rogers used was encapsulated lead zirconate titanate (PZT), a ceramic commonly used for transducers but not often used in biomedical devices. When you press the material, it generates an electrical signal. In an actual pacemaker system mechanical beating of the heart does the pressing. The device was attached to the hearts of living animal models, and the mechanical motion of the internal organs produced enough energy to charge a 3.8-volt battery. They found that placement was an issue; not every of the heart worked equally well. Placing the device on a heart ventricle at an angle seemed to work the best.

Thin ribbons of PZT are surrounded by flexible, biocompatible plastic. The entire package is approximately 2.2 centimeters by 2.5 centimeters.

Energy Harvesting

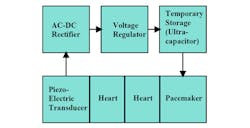

Fig. 2 shows a block diagram of an energy harvesting system that can power a pacemaker. The heart’s motion produces an output from the piezoelectric transducer, which is rectified and applied to a voltage regulator whose output is sent to temporary storage. The output from temporary storage powers the pacemaker that is attached to the heart. Each beat of the heart causes the accumulation of charge on a capacitor at the voltage regulator’s input. When capacitor’s voltage reaches a predetermined value it activates the voltage regulator’s output.

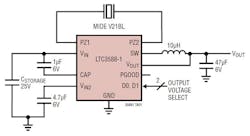

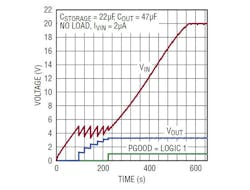

An example of an IC that duplicates Fig. 2 is Linear Technologies’ LTCR3588-1, which integrates a low-loss full-wave bridge rectifier with a high efficiency voltage regulator (Fig. 3). This forms an energy harvesting solution optimized for high output impedance energy sources, such as piezoelectric transducers. An ultra-low quiescent current undervoltage lockout (UVLO) mode with a wide hysteresis window allows charge to accumulate on an input capacitor in the initial start-up. As seen in Fig. 4, when the input capacitor reaches 4 V, the voltage regulator can efficiently transfer a portion of the stored charge to the output. When this occurs, PGOOD goes high and VOUT is applied to temporary storage. During this initial start-up, which is about 200 seconds, no power is applied to the pacemaker.

The LTC3588-1 is rated for 950 nA input quiescent current (output in regulation no-load) and 450 nA input quiescent current UVLO. Input operating voltage is 2.7 to 20 V, and output current is up to 100 mA.

In regulation, the LTC3588-1 enters a sleep state in which both input and output quiescent currents are minimal. The voltage regulator turns on and off as needed to maintain regulation.

The IC’s four output voltages, 1.8V, 2.5V, 3.3V and 3.6V, are pin selectable with up to 100mA of continuous output. However, the output capacitor may be sized to service a higher output current burst. An input protective shunt set at 20 V enables greater energy storage for a given amount of input capacitance.