Electrical isolation is not always necessary in LED drivers to comply with safety standards. Higher power LED light sources have now begun to replace HID lamps in street lighting, stage and stadium lights and also in some LED-based high bay lights. This trend is likely to continue as LED technology improves and higher lumens per watt performance is achieved in conjunction with longer LED operating life and inherent optical advantages offered by a directed light source.

HID lights are relatively difficult to drive since they require a very high ignition voltage (in the region of 20kV) when hot. Most ballasts are unable to deliver this voltage, making a hot re-strike impossible. They also suffer from the further disadvantage of arc instability, making them unable to dim below about 50% of maximum power rating.

Clearly, efficient high brightness LED light sources offer significant advantages in these applications, since they have none of these drawbacks. Several existing power converter topologies are used in LED drivers at power levels from 50 to 250W, covering these applications. Among these, the two-stage PFC front end plus isolated resonant half-bridge back end offers high efficiency and power density. However, this approach is avoided by some engineers because it is less widely used and the design process is more complicated than the basic switched mode power supply topologies.

An alternative non-isolated power converter can be used in place of this if the electric shock hazard is eliminated from the light fixture in a different way. This allows a simpler and cheaper LED driver to be utilized that still delivers comparable efficiency to the previously described isolated converter.

Approaching the safety issue from another angle has produced protecton schemes mechanically incorporated into the light fixture, by ensuring that electrical connection from the AC line to the LED panel is broken when the front cover diffuser panel is removed from the fixture. This is easily done by means of one or more switches built into the fixture, so that if any access panel is removed the electrical connection is opened. This approach to safety is equally as effective as using an electrically isolated driver. Although it adds cost and complexity to the fixture design, some manufacturers are designing LED lights based on this approach, enabling them to use a simpler LED supply. Such a power supply wound not conform to safety standards such as UL, but when incorporated into a suitable fixture would be compliant.

The most popular non-isolated LED driver design comprises a front end PFC stage based around the ubiquitous boost converter followed by a buck regulator that steps the DC bus voltage from 400 to 500V down to whatever voltage is required for the LED panel. The front end stage will be outlined briefly here; however, our main focus will be on the buck section.

The terminology used here to describe this power converter Boost+Buck, which should not be confused with Buck-Boost or Boost and Buck, which refer to different topologies.

The front end PFC stage converts the full wave rectified AC line voltage to the DC bus voltage. The voltage feedback loop responds slowly over many AC line cycle so that the MOSFET on time remains essentially constant during a cycle.

An advanced controller such as the IRS2500 increases the on time as the AC line cycle approaches a zero crossing to compensate for crossover distortion and reduce THD. The majority of controllers operate in critical conduction mode (the boundary between continuous and discontinuous conduction modes) where the off-time varies during the AC line cycle, producing an approximately sinusoidal AC input current in phase with the voltage. This technique is well known and used in many different applications.

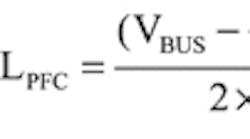

The PFC inductor value can be calculated from the following:

Where:

LPFC = Inductance in henries

VBUS = DC bus voltage

VACMN= Minimum rms AC input voltage

η = PFC efficiency (typically 0.95)

fMIN= Minimum PFC switching frequency at minimum AC input voltage

Pout= System output power

The peak current (iPK) in the PFC inductor is:

The PFC inductor should be designed such that it does not saturate at ipk and maximum operating temperature. This involves adequate sizing of the core and air-gap.

Since the back-end Buck stage of this converter is required to step down from a high bus voltage, there is a restriction on the minimum LED output voltage that may be used with acceptable efficiency. The switching duty cycle for a buck converter ignoring losses is given by the ratio between output and input voltage. Efficiency reduces as the duty cycle reduces. This is largely due to the switching losses which increase with input to output voltage difference.

From this, it becomes clear that this type of converter offers much better efficiency for high voltage LED loads, for example a 450V DC bus bucking down to drive a 200V panel of LEDs. Such a load would consist of many LEDs connected in an array with series strings containing in the region of 50 LEDs. Many high power LED light sources are now available that are made up of arrays of individual LED die packaged together. Several of these may be combined in a single light fixture to add up to a total voltage within the suitable operating range of 100 to 400V. Designers typically optimize the LED load configuration to operate at optimum efficiency, which in this case would be at the highest possible output voltage.

When considering the Buck stage’s design, there are some alternatives in LED buck driver configuration and control methodology. Where the load may vary over some range, for example 100 to 200V, hysteretic control is a good option since it is inherently stable and able to provide good regulation. In LED drivers, the level of high frequency ripple current is generally quite high in order to minimize inductor size and cost. This makes sense since most high brightness LEDs are able to withstand current peaks up to 30% above their maximum average current rating. That being the case, ripple current may be as high as 40%.

Average current control will evidently be more accurate than the alternative peak current control method since the difference between peak and average current is significant and varies depending on input and output voltage variations. Peak current control is an acceptable method for fixed load applications, however most LED drivers are designed to work over a range of loads. It is desirable for a single LED converter to be used in several different sizes and configurations of light fixtures, rather than needed a different model in each case.

Fig. 2 illustrates how the peak and average currents output currents become further apart as ripple increases. In this illustration frequency is fixed so the ripple would increase as the buck inductor decreases.

A hysteretic average current mode controlled buck LED driver can be configured either with a high side MOSFET as shown in Fig. 1, or with a low side MOSFET, as shown Fig. 3.

In the high side MOSFET configuration, the LED current sense resistor used to provide feedback for the regulator can be referenced to the circuit 0V bus, however the MOSFET is not so it requires a floating high side driver. Controller ICs exist that incorporate this function such as the IRS25401. This configuration can use a fast recovery diode as shown in Fig. 1 or a synchronous MOSFET to provide the off time switch.

The low side MOSFET configuration shown in Fig. 3. has the MOSFET source connected to the 0V bus so a simple low side gate driver can be used; however for hysteretic operation, the current in the high voltage bus must be sensed. Controllers that detect the current at the source of the MOSFET are available, however these do not operate in hysteretic mode.

The IRS2980 shown in Fig. 3 incorporates a differential high side current sensing scheme able to operate at voltages up to 450V. The current sense section of the IC resides in a floating high side well and uses level shifting circuitry to tell the gate driver to switch on when the differential voltage between the HV and CS inputs drops below the lower hysteresis limit and off again when the voltage rises above the upper hysteresis limit. In this way, the current is maintained at an average between the limits even when some overshoot and undershoot of the current occur, which happens due to propagation delays in the system. The freewheeling diode conducts during the MOSFET off time while the output current is falling. Since the circuit operates in continuous conduction mode (CCM) the diode must have ultra-fast reverse recovery (35nS) in order to minimize switching losses. The IRS2980 includes an on-board high voltage regulator that can supply VCC from the DC bus. Since this inevitably dissipates some power the designer can choose to supply VCC from another source in which case the regulator will shut off. The high side current sense circuitry also produces some power dissipation. Therefore, in this application it is necessary to add thermal relief around the IC. This technique is very effective for reducing package temperature rise in devices that dissipate power maintaining the die below its maximum rated temperature at ambient temperatures up to 60ºC.

Fig. 4 shows a section of PCB around an LED controller in an SO8 package mounted on the bottom side where copper has been added on the top side of the with vias to transmit heat away from the package to the surface. Potting compounds are also widely used, which further reduces the temperatures of all the converter’s components and extend operating lifetime.

PWM dimming of the LEDs can be included in the design with both circuit configurations. The IRS2980 includes an on-board dimming ramp generator controlled from a 0 to 2V DC control voltage. Either the IRS2980 or IRS25401 can be pulsed on and off with an external logic level signal if desired.

Buck LED converter stages usually operate in CCM in order to avoid high LED current ripple and the need for large output capacitors. The drawback to this approach is that the MOSFET will not switch on at zero voltage between the drain and source, resulting in some switching losses.

Using a larger inductor value and operating at lower frequency reduces these to a minimum. A capacitor can also be added to the output in order to reduce ripple which is another approach sometimes used to reduce inductor size. It is even possible to operate the buck converter in DCM if a large enough output capacitor is used which greatly reduces switching losses. This does, however, introduce some challenges in designs that use PWM dimming. While small output capacitors offer the benefit of noise filtering, large output capacitors can result in current surges occurring at the beginning of each PWM dimming burst. This may be eliminated by connecting the capacitor across the LEDs directly, so that the current sense resistor senses the capacitor current plus the LED current. Doing this, however, may delay the current rise time at the start of each dimming burst. Placing one capacitor across the LEDs and another before the current sense resistor can optimize current rise time.

Fig. 5 shows an example of current overshoot in red and slow current rise time in blue with an optimized rise in black. Where PWM dimming is used a slow rise time prevents accurate dimming to low light levels and an overshoot may overstress the LEDs and reduce operating life. In non-dimming applications, a slow rise time should present no problem, but overshoot is generally not acceptable. Even with optimized current rise time at the start of each PWM cycle, there is a practical limit to the minimum dimming level possible due to this rise time. Where no output capacitor is used, the minimum dimming level can be lower.

Tests carried out on a back end LED buck driver based around the IRS2980 controller operating in CCM from a 400VDC bus and driving a 200V LED load at 350mA produced an efficiency of 95%. In this case, the inductor value was 6.8mH with a 100nF output capacitor, a 500V MOSFET rated at 5A and 25nC gate charge with a 35nS 600V ultra-fast diode. The PFC front end boost stage typically has efficiency above 95%; therefore, the whole system can deliver an efficiency of greater than 90% at this 75W power level.

Related Articles

Buck Converter Losses Under the Microscope

LED Lighting Management IC Improves Power Factor and Efficiency

Using a Current Mode PWM Controller in Voltage Mode

Optimizing LED Lighting Systems For Efficiency, Size and Cost