What you’ll learn:

- What types of robots are proving useful in retail environments?

- The commercial and technical challenges of making robotics work in the retail sector.

- How wireless-charging solutions can alleviate some of the maintenance and replacement issues in retail robotics, helping to manage costs.

- Why industries like retail make robotics and power management a promising career area for electrical engineers.

The physical shopping cart of the future is here now, and it's as different from yesterday's unwieldy cage-on-wheels as a Tesla is to a 1990s Ford Focus. Futuristic shopping carts are now appearing in stores, and they carry digital entertainment systems, AI-powered cameras, and even entire virtual checkouts on wheels.

The smart shopping cart is just one type of robot that promises to change retail environments in the next few years. The robotic revolution in this sector is also a signal for electrical engineers: If you want to supercharge your career, consider specializing in new generations of mobile robots and the charging systems that power them.

Shopping for Innovation

Retailers often face slim margins and intense competition. This is why you'll often see grocery stores honoring their competitors' prices and frequently adjusting their own. They’re on the lookout for operational advantages that help cut costs and improve productivity to meet these challenges.

Digital carts are revolutionizing the retail experience, offering innovative solutions for a variety of shopping needs. Among the leading pioneers is Aisleworx, which has crafted retail carts tailored specifically for shoppers accompanied by children (see image above).

This state-of-the-art advertising platform is also equipped with a screen that plays digital educational content, engaging children while their parents shop. The cart is also paired with a media-enabled docking station that extends marketing reach while also managing the cart system.

Some carts directly help with the act of shopping. Amazon's Dash Cart uses built-in cameras and computer-vision algorithms to recognize items placed into the cart, while also weighing them. This enables customers to pay automatically without queuing at a checkout.

Some autonomous shopping carts, like ELI, even push themselves around the store while leading shoppers to the right aisles. Then these smart carts take items to the customer’s car, trundle back to the store alone, and queue at a charging station, all of which eliminates the hassle of manually returning the cart.

Retailers' need for innovation is creating a strong market for these products and driving revenues from the robotics industry to all-time highs. Market research company FactMR expects revenues from automated guided carts alone to grow from $208.7M in 2022 to $462.7M in 2032, representing an 8.3% CAGR.

Retail Robotic Apps Go Beyond Carts

Carts are just the start. There are plenty of other retail robotic applications. Automated floor scrubbers make light work of cleaning large retail shopping areas. Inventory scanning robots roam the aisles checking for inventory that needs restocking, while also looking out for incorrect price labels or promotional signage. The LoweBot travels around the shop floor answering basic customer queries and guiding people to the items they need.

As the CEO and co-founder of BattGenie, Manan Pathak has a ringside view of the entire robotics ecosystem, including retail robots. His company develops battery-management systems for everything from electric vehicles to industrial robotics applications and drones. The coming surge in demand for battery innovation is already well documented. What isn't so visible is the demand for human talent that comes with it.

Robots like those in retail will need to be as efficient as possible, working as long as possible to pay for themselves, explained Pathak. That requires a multidisciplinary effort to improve battery health and performance.

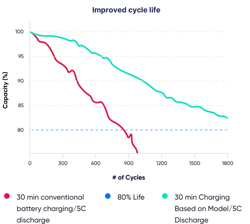

"At BattGenie, we are focused on software for efficient battery use and charging, delivering up to three times more battery life (see figure). Others are looking at hardware sensing solutions to ensure you don't actually overcharge or over-discharge," said Pathak. "So, there are multiple approaches that people are taking to target the same problem of extracting more energy, improving life, and reducing charge times."

Retailers Confront Another Type of Charge

The need for efficient power requires an understanding of two elements: the battery and the charging mechanism that supports it. Each of these has its own technical and economic considerations.

Whether it's powering scanners and screens on push-along carts or self-propelled robotic devices roaming the aisles, the health of a battery is crucial when evaluating periodic costs like maintenance truck rolls and parts replacement.

Depending on the application, robots in retail typically use either lead-acid battery technology dating back over a century, or modern lithium-ion technology. Managing the health of the battery is important; both types of battery chemistry have similar issues, explained Pathak.

"Every battery is rated to operate in a particular voltage window," said Pathak. "Operating the battery safely within that window will give the three or four years of life that the manufacturer provides under warranty."

The temptation might be to charge more quickly at a higher voltage to increase the operating time of a cart or floor scrubber, but higher voltage charging affects the depth of discharge (DoD), which is the energy depleted from the battery relative to its total capacity. Driving DoD too high can shorten battery life, as can leaving the battery discharged for too long. Conversely, leaving a fully charged battery connected to a charger can also degrade components, including the electrolyte.

Limiting battery life isn't the only danger of inappropriate charging and DoD—it can also cause immediate operational problems. Many lithium batteries have battery-management systems that completely disconnect everything for safety reasons when the voltage to the cell drops below a threshold. This eliminates the danger of a battery fire but cuts power to the robot completely, disrupting operations.

It's easy to understand these safety measures. Battery health problems can become catastrophic in lithium-ion cells that fall below a certain voltage too many times, or which are constantly kept on full charge. The liquid electrolyte may become gaseous, swelling the battery. The problem is common enough on consumer devices that there's a whole subreddit—called “spicypillows”—dedicated to them.

Lead-acid batteries will also lose capacity when their DoD goes too high. On top of that, they can suffer from poor efficiency due to sulfation, where the anode produces an oxidation layer that impedes current flow.

The Commercial Challenges of Poor Battery Health

For a consumer, a broken battery means simply buying a replacement battery online or possibly sending their phone or laptop back to the manufacturer for a repair. For retailers, replacing some of the high kilowatt-hour batteries used in robots is far more expensive. For instance, a large autonomous floor scrubber can use four very large and specialized batteries at a cost of over $800 per battery.

One of these challenges is the density of robot allocation. In more established markets such as warehousing, robotics customers typically install a relatively large number of robots in a few locations around the country. Robotic automated storage and retrieval systems might coexist with mobile autonomous devices that lift and carry packages around the warehouse floor.

Conversely, retailers often have many locations spread around the country, each containing relatively small numbers of robots. This changes the economics of maintenance and repair.

Most of these outlets will not have on-site expertise to maintain their robots. Instead, a visiting technician must come and swap out the battery, involving costly truck rolls as well as the cost of the unit itself. In some cases, units can’t be easily repaired in-store. Instead, large complex units like floor scrubbers must be sent on a truck back to a centralized repair center, which can be hundreds or thousands of miles away.

All of this boils down to one essential takeaway: For robots in retail environments, every day of battery operation counts.

The Difficulty of Contact-Based Charging

If charging too infrequently or too much can negatively impact a robotic cart, then why not simply charge them the right amount? This turns into a problem in busy retail environments that use contact-based charging mechanisms.

One of three operators must plug in a robotic cart—either the customer who was using it, an employee, or in some rare cases, the cart itself under its own propulsion. Each of these scenarios comes with its own challenges that can disrupt the charging cadence.

Contact-based chargers are less tolerant than wireless ones, relying on more precise positioning that in turn demands more human attention.

Customers have neither the time nor, in many cases, the inclination to properly connect a cart with a charger. Even if that simply means guiding it into a charging bay. Customers frequently leave carts stranded, or they get them close to the charging bay but don't bother pushing them in properly.

Employees in typically lower-salary environments will often be too busy to roam around retrieving carts. Cart-hunting might be done at irregular intervals, leaving batteries to over-discharge and fail prematurely.

Customers and employees who push the carts into the charging bay might do so haphazardly, failing to connect them well with a contact-based charger. Constant banging and smashing will also damage the charging contacts. A self-propelled smart cart or other retail robot might try to dock itself at a contact-based charging station, but there’s a very narrow margin of error exists—no contact means no charge. There’s also always the chance that discarded boxes or other detritus could prevent autonomous carts from docking with the charger.

The challenges of contact charging in a retail environment can easily lead to poor battery health in robots and powered carts because charging isn't likely to be regular.

Better Battery Health Through Programmable Wireless Charging

Wireless charging solves many of the problems associated with contact-based charging in retail environments. Wireless-charging docks use coils instead of contact-based pins or plates to charge. Instead of connecting directly with the charger, the carts charge through the air.

WiBotic's solution leverages resonant charging, in which the Tx and Rx coils use identical frequencies that deliver more power over longer distances, offering higher range tolerance between the charger and the robot. As a result, autonomous retail robots can dock themselves more easily while ensuring a healthy charge. It’s also easier for employees and customers to dock retail carts themselves.

However, improving charging reliability is only part of the solution. Once the robot or cart is properly docked, it’s equally important for the charger to understand the condition of the battery and take steps to properly charge it. For instance, instead of fully charging a battery, the charger can be programmed to keep the robot within a charge window of 20% to 80%. Charging a battery to within this range means that it will need to be docked slightly more frequently, but it also promises to double the robot's battery life, explained Pathak.

He added, "If you charge from 0% to 100%, you'll get x cycles out of the batteries." Charging with constant currents when 30% full, until the battery reaches 80%, only charges the battery with half (50%) of its energy capacity. Though it would take two such charging cycles to deliver the equivalent of a full charge to the battery, this half-charging is easier on the chemistry.

“Charging this way means you can actually get more than 2x life out of the batteries,” said Pathak. “This approach is still suboptimal as it compromises the usable energy and corresponding runtime per charge cycle. A more efficient approach is to change the charge current dynamically with the state of charge that minimizes battery degradation per cycle, and allows you to put the full 100% capacity in a given charge time. But the significantly lower battery degradation extends battery life by more than 2X.”

Wireless chargers can more easily monitor a robot's battery charge to make these kinds of charging decisions. Plug-in chargers generally have the charging circuitry in the charging dock rather than on the device, meaning that they're blind to a robot's battery condition when it’s not docked.

Conversely, the nature of a wireless-charging system requires the charging circuitry to be on the device rather than in the charging bay. This enables on-device power-management systems to constantly monitor the voltage on each robot's battery and send it wirelessly to a central management unit. The central unit can alert store managers that a cart/robot's battery is getting low, so that it can be plugged in and kept healthy.

Because the charging circuitry is on the device, it’s also easier for a retailer to install multiple, cheaper charging bays around the retail location. This makes it easier to charge both human-guided and autonomous robots.

Promising Career Opportunities in Wireless Robotic Charging

Robotic charging will become increasingly important in retail as stores look for better customer experiences and new efficiencies. Wireless charging carries significant advantages for unforgiving retail environments. Understanding the nuances of wireless charging will help engineers push into growth areas like these.

"There is need for added innovation and more people who can actually pursue that as a field," said Pathak, adding that the hardware companies solving robotics and wireless-charging problems face tough technical challenges. “You need more people who can actually do that.”

He also pointed out that these skills will become even more important as the U.S. tries to wrestle more independence in technology hardware manufacturing away from China. "We need that expertise in the U.S. to scale up."

As retailers put more robots on their shopping lists over the next few years, this will create other demands in the ecosystem, including the demand for technical human talent. Electrical engineers exploring robotics and wireless charging have plenty of opportunities ahead of them. Stocking up on these skills will serve them well when shopping for lucrative jobs in the future.