Designers of switch-mode power supplies generally put a lot of care into selecting the placement of poles/zeros of the supply transfer function to ensure stable operation. However, many such designs convey secondary-side information in a feedback loop across an isolation barrier to reach the non-isolated primary side. This introduces complications in the analysis.

There are several methods of crossing that barrier, but the most widely used employs an optical component called an optocoupler. The device affects the transfer function through such parameters as its current transfer ratio and transmission pole. Knowing how to characterize these parameters and understanding how they change is vital to designing reliable and efficient converters. Failure to account for the presence of its characteristic elements during the design phase will lead to either a sluggish loop response or worse, a conditional stability subject to unavoidable production spreads. In contrast, understanding how its parameters move and influence the converter stability is key to making sure they will stay silent during the converter lifetime.

First a few basics about optocouplers. As a quick review, an optocoupler is made of a bipolar transistor and a gallium arsenide (GaAs) light emitting diode (LED) element. Encapsulated into a plastic package, it can provide galvanic isolation from 2.5 kV to 6 kV between a transformer-isolated secondary side and the primary side of a converter.

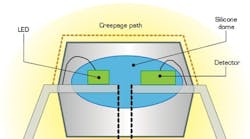

There are several ways of manufacturing optocouplers. Among them, the planar technique consists of laying the diode and transistor in the same plane, then wire-bonding them to a common leadframe. A silicone dome typically reflects the LED beam to further route it to the transistor collector-base junction. The base of the transistor collects photons emitted by the LED to give birth to a collector current with no electrical contact between the LED and transistor connections.

The collector current Ic flowing in the transistor depends on the quantity of photons from the LED. As the light intensity directly depends on the LED biasing current IF , there is a relationship between both currents. This is the current Transfer Ratio, CTR, defined as:

The CTR is affected by a lot of external parameters: temperature, LED current, transistor gain dispersions etc. Examining the effect of the LED forward current on the optocoupler CTR, one can see the wide variations of these parameters with changes in the LED current.

Modern consumer power supplies, where every milliwatt counts in the no-load standby power performance, reduce the LED driving current to a few hundreds of microamperes. As a result, the CTR collapses and can suffer from wide lot-to-lot dispersions. For a given optocoupler, a CTR range of 60 to 120% is not uncommon when the LED is biased in the vicinity of a few milliamperes. This number shrinks to less than 30% when operated at a 300-μA LED current, showing a division by four or -12 dB when used in a gain chain!

Many switching supplies employ the widely used TL431 op amp and an optocoupler to form an efficient secondary-side control circuit. One such circuit diagrammed in the accompanying figure forms a type 2 compensator. Based on this architecture, it is possible to show that the transfer function follows the equation:

Where:

Rpullup is the optocoupler loading resistor; RLED is the LED series resistor; and C is the parallel combination of the optocoupler parasitic capacitance and the added capacitor C2. G is an indication of the gain needed to cross the 0 dB axis at a selected crossover frequency.

It is clear from the relationships above that the CTR plays a role in the so-called mid-band gain. Usually, this mid-band gain compensates the gain deficiency of the output stage at a frequency where you want pole(s) and zero(s) of the transfer function to cross over at a specified phase margin for the purpose of operational stability.

Designers who made compensation calculations based on the highest CTR of 120% might experience a strong error in the crossover frequency if the CTR barely reaches 30%. In theory, the designer strives to ensure the loop gain magnitude passes the 0-dB axis with a slope of -1 to keep the phase rotation at this point under control. If the loop gain drops 12 dB because the CTR jumps from 120% down to 30%, the crossover frequency drops by a factor four: You initially had 1 kHz, you end up with 250 Hz! If the available phase margin is limited in this new crossover area, the converter can experience instability problems and will fail at final test. It is thus the designer's duty to understand the CTR variations of the device and realize how unavoidable production dispersions can degrade the phase margin at crossover.

The optocoupler pole

The photons emitted by the LED are collected by the collector-base area of the bipolar transistor found in the optocoupler. To maximize the collected flux, the concerned area is purposely enlarged to the detriment of the parasitic capacitance between the collector and the base. Associated with the transistor gain, β, the Miller equivalent capacitor severely hampers the compensator phase margin when used in a compensator circuit such as that diagrammed here. A simplified small-signal version of the optocoupler includes an equivalent capacitor appearing between the collector and the emitter. One can observe this capacitor couples with the pull-up resistor (or the pull down in a common-collector configuration) and introduces a low-frequency pole at a frequency fp:

It is important to note that when used in conjunction with the architecture diagrammed here, the optocoupler does not add another pole. However, its equivalent parasitic capacitor Copto comes in parallel with C2 and displaces the pole you thought you had correctly positioned in the frequency domain. Therefore, once the optocoupler capacitor is known, it must be subtracted from the needed capacitor C to ensure the sum of Copto and C2 gives the right value:

C2 = C-Copto

(7)

If Copto is larger than the desired C, there is no solution. The designer must explore a new pole/zero combination, probably via the reduction of the selected crossover frequency.

There are several ways to determine the optocoupler pole position. Perhaps the easiest is to read the data-sheet and look for frequency response curves or timing diagrams. But the best, in my opinion, is to setup a quick test fixture and ac-sweep the optocoupler alone. That confirms that the dc conditions and the component selection exactly match the converter implementation.

The accompanying figure describes how the optocoupler can be wired to reveal its pole position. The Vbias source fixes the dc operation point of this common-emitter configuration. It will take some adjusting to bring the optocoupler collector around (for instance, 2 V if Vdd = 5 V), ensuring enough voltage dynamics when the ac sweep will begin. Note that both Rpullup and RLED share a similar value, bringing the low frequency ac gain to the CTR value as described by (3).

Rbias can be selected to be around a few kâ¦. But it will affect the transmission gain by diverting the ac-modulated current from the LED. However, because we only care about the pole position, Rbias does not play a big role. The easiest way to ac-sweep the circuit uses a network analyzer which will compute 20log10 [V(B)/V(A)]. The Bode plot will thus immediately appear in the computer screen.

Looking for the -3-dB deviation from the low-frequency flat plateau will indicate the pole position. This is what the accompanying figure shows where the pole lies at 10 kHz. For this particular test, which used an SFH615A-2 opto coupler, the pull-up resistor was set to 4.7 kâ¦, imposing a maximum collector current around a milliampere from a 5-V Vdd bias source. Changing this resistor to 15 k⦠rolled the pole back to 4 kHz. With a 10-kHz pole and according to (6), the optocoupler capacitor is 3.4 nF. In the figure it is evident that changing the dc operating point (different Vce voltages) does not affect the pole position.

Without using a network analyzer, it is still possible to find the pole position. Use a sinusoidal function generator for the ac source and observe the collector voltage with an oscilloscope at, say, a 100-Hz frequency. Make sure the modulation is small enough to avoid distorting the observed signal. Tweak and offset the oscilloscope vertical channel to have the signal centered at the dc collector voltage, thus equally covering the 5 divisions up and down from the middle of the screen. Then, change the frequency and increase it until the modulation peak amplitude drops to around 3.5 divisions (total 7 divisions peak to peak). This point corresponds to a -3-dB drop from the reference point at 100 Hz: this is the pole frequency.

LED dynamic resistance

In equation (2), the overall gain expression only depends upon external elements: the optocoupler CTR, the pull-up resistor, and the LED series resistor. However, the LED series resistance is bounded by dc operating conditions imposed by the diode forward voltage (≈1 V) and the TL431 minimum operating voltage (2.5 V). As a result, in low output voltage applications (e.g. 5 V), the series LED resistor can be of low value, in the vicinity of a hundred ohms. In that case, the LED dynamic resistance Rd can no longer be neglected. Furthermore, the bias resistor commonly installed with the LED carries a portion of the feedback current and also affects the total gain. A simplified ac schematic highlights the elements around the LED. These small effects are often overlooked but they can explain gain discrepancies observed in certain cases.

A few equations can help to formalize the role played by these elements and show how they interact with each other. The feedback voltage depends on the pull-up resistor and the current in it:

VFB (S) = Ic (S) Rpullup = IL (S) Rpullup CTR

(8)

The full ac current I1 splits between the LED and the bias resistor. However, the LED current alone passes through the feedback chain. Therefore, the bias resistor “steals” away current from the loop. In terms of ac behavior (Vf is constant and equal to 0 in ac), the LED current is expressed by:

The full gain chain includes the LED series resistor and the bias generator. Both of them can affect the gain. Substituting (9) in (8), we can extract the transfer function for the optocoupler chain alone:

In this expression, both Rd and Rbias play a role. Rbias is often set to 1 k⦠to provide the necessary milliampere current for the TL431 op amp. If Rd is small compared to this value, Rbias will divert less ac current and the gain chain will not suffer from their presence. In contrast, if Rd becomes non-negligible, the whole chain undergoes a gain reduction. What dynamic resistance value does an LED exhibit?

The accompanying figure shows the characterization of such a device at different bias currents and operating temperatures. As expected, the dynamic resistance varies depending on the operating current, as would be the case with any diode. The dynamic resistance is determined by first looking at the curve in the vicinity of the operating point and then is computed as the voltage variation obtained by a small current change around the considered bias region:

From the accompanying figure, a dynamic resistance of ≈ 160 ⦠is calculated with a 300-μA collector current. This is the case with modern PWM controllers that strive to reduce the consumed power in no-load conditions by hosting a high-value internal pull-up resistor (usually between 10 and 20 kâ¦). When the pull-up resistor is lowered to impose a 1-mA forward current (Rpullup = 1 kâ¦), the dynamic resistance drops to ≈ 40 â¦. Applying (10) to a 5-V converter featuring the following element values - RLED = 150 â¦, CTR = 0.3, Rpullup = 20 k⦠- we can compute the gain for various LED dynamic resistances:

G1IRd = 0⦠≈32 dB

G2IRd = 40⦠≈30 dB

G3IRd = 160⦠≈25 dB

(12)

It's evident there is 7-dB gain difference from a calculation assuming a zero dynamic resistance and the reality of a LED operated at a low forward current. Again, a 7-dB difference in the mid-band gain can engender a crossover frequency mismatch of 2.2: you shoot for a 1-kHz crossover point and you end up below 500 Hz!

Good design practice

Clearly the CTR, the LED dynamic resistance, and the parasitic pole can influence optocoupler response. The key element to improving any of these offenders depends on the performance you are looking for. If an extremely low standby power is important while charging batteries (a notebook adapter, for instance), a wide bandwidth is probably not mandatory. The circuit can cope with a rather high pull-up resistor and a low collector current. The correspondingly low CTR associated with a low-frequency optocoupler pole will not hurt the performance at the end, as long as their natural variations are well accounted for in the design cycle.

But if time response and bandwidth are the key elements of the specification, be sure to select a low pull-up resistor value (1 kâ¦) to extend the optocoupler pole well beyond the crossover point and also reduce the LED dynamic resistance. At the end, once the design is frozen, it is the designer's duty to explore all the possible element variations with temperature and lot-to-lot dispersions to keep enough phase margin in all possible cases. Applying these rules is part of the recipe to a seamless mass production. n

References

For details about opto coupler assembly techniques, T. Kek, L. Tan, “Stacked LED makes Compact Optocouplers”, EE Times Asia, April 2005

For more detail on switch-mode supply design, C. Basso, “Switch Mode Power Supplies: SPICE Simulations and Practical Designs”, McGraw-Hill, 2008