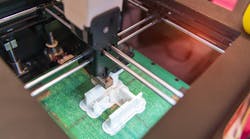

As the manufacturing industry continues to evolve, more and more technology is being used to help make the production process more efficient, effective and safer. A form of additive manufacturing, 3D printing is becoming increasingly common in the aerospace, automotive, medical device and other sectors that rely on complex parts to produce their finished products.

With 3D printing, those complex parts can be made more cost-effectively and efficiently than companies can produce using more traditional means. Specifically, automakers can use 3D printing to develop tooling and prototypes for new car models, and medical device makers can use the technology to make custom implants, prosthetics and surgical tools.

Some of the more notable uses of 3D printing include the time NASA took a printer into space and successfully used it on the International Space Station. “What had long been theorized in sci-fi became a reality and potentially signals the future of the 3D printing industry,” Justin Haines writes in History of 3D Printing: When Was 3D Printing Invented?

“Back on Earth, multiple companies worked to not be outdone by NASA and space, most notably in the medical field,” Haines continues. The first came in 2015, when CELLINK announced the first commercial sale of “bioink” that allows the 3D printing of body tissue. “This was quickly followed in 2016 with a Dublin lab announcing that they could print human bone or cartilage,” Haines writes.

An equally impressive milestone was achieved in 2018 when a family moved into the first fully 3D-printed home. “While originally envisioned as a cost-effective way to build affordable homes around the world, the technology continues to evolve with homes recently being built for luxury buyers,” Haines adds.

Heading for the $9 Billion Mark

According to IBISWorld, 3D printer manufacturing revenue has posted a compound annual growth rate (CAGR) of 14.6% to $7.7 billion over the past five years, including a 19.1% increase in 2023 alone (when profit increased to 3.9%).

The research firm says 3D printers have become more attractive as prices declined. Prices for commercial 3D printers typically start at $5,000 and can go as high as $500,000, depending on the printing process and materials,” it points out. “Desktop 3D printers are less expensive, with a typical price range of $200 to $1,000. The development of lower-priced 3D printers makes the technology more attainable for the general public.”

3D printing, also known as additive manufacturing, has already helped improve the manufacturing process across several industries, including the automotive industry. According to a report by SmarTech Analysis, the global market for 3D printing in the automotive industry is expected to reach $5.3 billion by 2027, growing at a CAGR of 26.3%.

Specific to the automotive manufacturing market, Chip 1 Exchange says 3D printing offers several advantages to traditional manufacturing methods, including reduced time and cost of producing complex parts and prototypes. 3D printing also enables manufacturers to produce parts with greater precision and accuracy, reducing waste and improving efficiency.

Additionally, Chip 1 says 3D printing can make customization for individual customers easier to implement, thus improving customer satisfaction. “With the onset of 3D printing using metals, parts developed using 3D printing technologies are lighter than their usual metallic counterparts and can provide better fuel efficiency, especially for industries that require it,” the company points out. “Therefore, more lightweight specialized components that are 3D printed will improve a vehicle’s overall fuel efficiency simply by trimming down the fat.”

Acknowledging the Limitations of 3D Printing

As with any innovative technology, 3D printing also presents a few downsides that manufacturers and their procurement teams should be aware of. These include:

- Limitations on materials (since not all plastics or metals are viable for 3D printing applications).

- Print size being limited due to the smaller print chambers of the 3D printer itself; therefore, more extensive parts must be printed into segments that are later put together or assembled after production.

- Some 3D prints also require post-processing steps, such as cleaning up excess or support materials.

“While 3D printing is excellent for quick prototyping, it becomes more costly when mass-producing a large volume,” Chip 1 points out. “Also, as this technology becomes more and more available to the public, fake and counterfeit products may start to proliferate, and it will be difficult to determine authenticity.”