When a design engineer gets the idea of harvesting energy from some kind of vibration, here is the typical starting point: “They know they have a vibration, they know they want to use it, but apart from that, they know very little.” So says Brian Durant, technical sales manager for Mide Technology Corp., a maker of transducers used to harvest vibrational energy. “We have to walk people through the design, educate them about their vibration and about what kind of power to expect,” he says.

Durant isn’t the only one seeing this kind of cluelessness. “A lot of times our customers aren’t sure of their environment. Step one is to figure that out. What kind of motion frequencies and amplitudes are you really dealing with? There are a lot of ways to get that information,” says Steve Arms, founder and chief technical officer of MicroStrain Inc., another supplier of vibrational transducers for energy harvesting.

One of the first facts potential harvesting designers need to understand is that off-the-shelf vibrational harvesters are generally hand made. This generally keeps the price of these devices in the range of $50 and up.

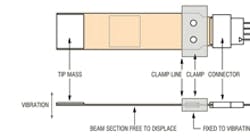

For example, harvesters from Mide are made from bulk piezoelectric material configured as a cantilever beam with weight on the tip. The weight is a piece of tungsten attached by hand with bee’s wax. This transducer harvests relatively low-frequency vibrations in a sweet spot that is usually below 300 Hz. The lowest frequencies this design has been deployed to harvest is about 10 Hz., Durant says.

MicroStrain uses an electromagnetic transducer to harvest vibrational energy in the range of a few hundred hertz. Off-the-shelf designs employ a magnet moving through a coil. MicroStrain uses a piezoelectric material to harvest higher frequencies. The piezo material sits in a frame such that it is at a mechanical disadvantage. The frame is EDMed from a single piece of material.

None of these transducers are made with high volumes in mind. In fact, both companies say off-the-shelf vibration transducers generally get used only as prototyping tools. Once the concept has proven out, designers usually come back for a custom-designed transducer. The custom part can be tuned for the frequencies of interest, and it often is made in volumes sufficiently high to justify automated assembly methods that reduce its cost.

For example, Mide can adjust both the dimensions on its cantilever beam transducers and the amount of weight attached to the cantilever tip.

MicroStrain typically adjusts the resonant frequency of its piezo transducers by changing the dimensions of slots EDMed into the frame holding the piezo material.

Characterizing vibrations

The typical approach for characterizing vibrations is to install an accelerometer that gauges the amount of energy available for harvest. The increasing use of harvesting schemes has resulted in accelerometers being packaged with vibration characterization in mind. A device in this category is the SlamStick. Developed by Mide, it is billed as a high-speed ultra portable rechargeable data logger capable of measuring acceleration in all three axes.

The device uses a USB port for on-the-fly configuring, charging and downloading of data. Configuration software lets users tailor the device to check out the vibrations that the potential application presents. The configuration options include an adjustable delay time before each measurement, different measurement durations, and a trigger based on a pre-determined acceleration level. The device comes with analysis software that lets the user determine the frequency content of the monitored vibration.

In the same vein, MicroStrain has worked with several military applications to figure out the vibrational environment of helicopters. In one case, the firm provided wireless accelerometers that were battery powered for gauging the vibrations on a helicopter rotor. The output from a battery powered triaxial accelerometer got played back into a shaker table that reproduced the vibrational environment of the rotor. Engineers then put a prototype harvester on the shaker table and adjusted such parameters as the resonant frequency and stiffness of the mass to optimize the device. Reproducing the expected vibrations on a shaker table also gave engineers a way to test the optimized harvesters.

Gauging periodic vibrations this way is relatively straightforward. Doing so with non-periodic vibrations, as might arise from a door slamming, would require a bit more effort. “You’d have to get creative with that kind of application,” says MicroStrain’s Steve Arms. This sort of single-impulse situation might even be appropriate for the use of Weigand wires, he says. But in general, the management of pulse-type events is a bit more tricky than that for periodic vibrations.

Characterization of this sort is necessary because the harvesting of different vibration amplitudes and frequencies can entail a need for radically different harvester designs. For example, MicroStrain once devised harvesters that gathered vibrational energy from the control rods on an Apache helicopter. The predominant vibration was at between 4.3 and 5 rev/sec. This low rate, explains MicroStrain’s Steve Arms, called for a mechanical device whose mechanical compliance matched the mechanics of the environment. The firm came up with an electromagnetic harvester containing magnets moving through coils with the coils wound to get the necessary electrical impedance.

An inductive harvester of this sort, says Arms, tuned to between 4 and 20 Hz and experiencing 200 milliG, will produce between 3 and 4 mW. The stiffness of the structure in the case of the helicopter rotor was about 1,000 lb/in. and the rotor surface might experience displacements of about 6,000 µin. In contrast, a piezo harvester designed for a gearbox with an input of 1 G and input of between 800 and 2 kHz might put out 100 mW. Gearbox stiffness is typically on the order of 5 million lb/in. and the gearbox surface might typically displace about 30 µin. at frequencies on the order of 1 kHz. So the stiffness of harvester should be appropriate for the frequencies it will encounter, he says, matching the stiffness of what it attaches to.

Reducing costs

Transducer makers understand that they could drastically boost the size of the harvester market by figuring out ways of making their devices less expensively. There are efforts underway to do just that.

MicroStrain, for example, says it has come up with an electromagnetic harvester for frequencies near 20 Hz that “has the cost scrubbed out.” The device, they say, has already qualified to withstand Mil Std 810 environmental specs but has not yet reached patent pending status.

However, there is another way of reducing harvesting costs that might be more fruitful than attacking the cost of the transducer itself: reduce the amount of power necessary to run the circuits that depend on harvested power. “I think that is part of the solution,” says MicroStrain’s Steve Arms.

Circuits that could run at power levels on the order of 150 µW, for example, would be candidates for getting their juice from patches of piezoelectric material pasted on the surface of vibrating machinery, rather than from conventional harvesters. Bolstering that view are tests showing that the strain on helicopter control rods, is sufficient to power small circuits. In one case, eight patches of piezoelectric material were able to produce 8.5 mW, 62 nW/cm²/µE at 5 Hz, from a control rod during level flight.

And the idea of harvesting vibrations from machinery suggests another use for the technology. “I think machine monitoring is the next big application for vibration harvesting,” says Steve Arms. “It would be particularly helpful where machine downtime causes a lot of problems. You could amass a lot of information about failure modes this way, to the point of being able to know when a welded joint is going to fail, or which operators are beating up the machine. And the sort of condition-based maintenance this would make possible would let you tell customers at what point in the future they could expect their machine to fail.”

Resources

Mide Technology Corp., www.mide.com

MicroStrain Inc., Williston, Vt., www.microstrain.com

Getting the most out of a door slam

A lot of vibration energy harvesters use a beam made of piezoelectric material as a transducer. Vibration energy moves the beam and in so doing generate electricity. This scheme works particularly well when the ambient vibrations have a low amplitude and the vibration energy is mainly at one frequency. The dimensions of the beam can then be tweaked to resonate at the frequency of interest.

This type of transducer doesn’t work as well when the vibration energy covers a wide band of frequencies or is unpredictable. Transducers able to harvest vibrational energy in such settings may need a special design optimized for a variety of frequencies.

That was the case for a harvester designed to go on the rotor assembly of a Sikorsky H-60 helicopter. The predominant vibration frequency was that of the rotational rate of the rotor assembly times the number of rotor blades. With four rotor blades and typical rotational rates of about 4.3 Hz, the predominant vibration was at about 16 to 17 Hz with G levels varying from about one to five Gs. Pitch links or control rods on the chopper, which vibrate with the rotational rate of 4.3 Hz, also contain higher frequency components.

The scheme devised by engineers at MicroStrain to harvest these wide-ranging vibrations consisted of piezo material put in a framework under compression. It is bowed in its natural state and stable in two positions (bistable). Engineers there came up with both a beam-shaped and bowl-shaped piezo transducers which would snap suddenly from one position to the other when hit with enough inertial load at a wide range of frequencies. The range of response can be tailored by adjusting the mass or stiffness of the piezoelectric flexure and its dimensions. It can also generate electricity from a single event such as a door slam as long as there is enough energy to snap the device to its other stable position.

The material under compression needn’t be piezoelectric; in some cases, it could simply be a base material to which piezoelectric patches are bonded. Engineers say they’ve seen signals as high as 200 V generated by such devices when they snap.

How to harvest energy from strain

One of the promising areas for energy harvesting lies in using the strain on structural members to generate electricity. The amount of power available depends on the strain amplitude, frequency, and the area available to be harvested.

A feel for what kind of energy levels are available from this type of harvesting can be gained from work done by MicroStrain and Bell Helicopter on the control members of a Bell helicopter rotor. Researchers bonded patches made from the piezoelectric material PZT on to the mast. The eight patches each measured 2×5 cm. They generated about 2.5 mW during straight level flight. The PZT material didn’t fatigue after 10,000 flight hours with a dominant frequency of 6.8 Hz. The strain levels involved were relatively low, about ±35µE. The generated power was used to run a wireless sensor.