Matt Cuhadar is a key member of the Ametherm team, Matt Cuhadar has provided support for the company's customers as an application and sales engineer for the last two years. He holds a B.Sc. in engineering from Middle East Technical University.

Q: How do you choose the right type of NTC Thermistor to limit inrush current for capacitive applications?

A: Inrush current refers to the maximum, instantaneous input current drawn when power is applied to an electronic system’s power supply. A dc system has an input capacitor and an ac input system has and input rectifier and capacitor that can exhibit high inrush current when the associated equipment turns on. If steps are not taken to minimize this inrush current, it can damage power devices and reduce equipment life. A safe and cost effective way to reduce inrush current is to use an inrush current limiter (surge limiter), which is a special type of negative temperature coefficient (NTC) thermistor.

Inrush current occurs at the moment the power switch is thrown. This happens because the input filter capacitor acts as a short and its minimum equivalent series resistance (ESR) and line resistance are only a few milliohms, which can lead to a high inrush current.

Four factors can affect inrush current:

- Energy of the inrush current

- Minimum resistance required by the NTC thermistor (at t = 0)

- Steady-state current

- Ambient temperature

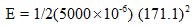

We’ll present the details of these four items. First we will look at the energy of the inrush current, which is caused by input capacitors expressed as:

Where:

E = Energy of the inrush current

C = Capacitance value (F)

VPEAK= Resultant peak voltage

The minimum resistance required by the NTC thermistor will vary from one application to another, depending on the line voltage, peak inrush current, and the desired inrush current limitation due to fuse and circuit breaker ratings. As a rule of thumb, if the maximum allowable inrush current is not known, either the diode bridge specifications or the oscilloscope readings of the inrush current will dictate the minimum resistance required by the NTC thermistor. Typically, one third of the observed inrush current from the oscilloscope readings is acceptable.

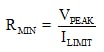

For Example:

Where:

RMIN = Minimum resistance required by the NTC thermistor at t = 0 and temperature = 25 ºC

ILIMIT = Desired inrush current limit

The operating current must be at or below the steady-state current rating of the NTC thermistor.

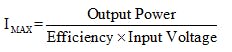

The maximum steady-state current can be found by:

Where:

IMAX = Maximum steady-state current

Output power = Output power of the transformer

Efficiency = Efficiency of the transformer

Input voltage = Minimum input voltage

In some applications, the NTC thermistor is bypassed with a timed relay after the inrush current. Even though the thermistor is out of circuit during operation, it is best to select a thermistor that can handle steady-state current in case the relay fails.

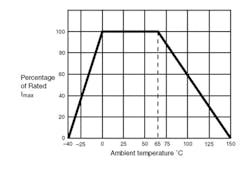

Ambient temperature will dictate if there is a need for:

- De-rating of resistance

- De-rating of steady-state current

The rated resistance of the NTC thermistor is at 25 ºC, so de-rating of the resistance rating will be needed for ambient temperatures above 25 ºC, as the resistance of the thermistor will be lower. Ametherm (resistance/Time) R/T curves will dictate how much de-rating is needed.

This file type includes high-resolution graphics and schematics when applicable.

The plot in Fig. 1 is used to de-rate steady-state current.

Example:

To illustrate, assume the values below:

Line voltage = 110 V

Steady-state current = 10 A

Capacitance = 5000 µF

Ambient temperature range = 10 ºC - 35 ºC

Desired inrush current limit = 30 A

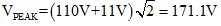

To calculate the peak voltage (VPEAK), we have to take line fluctuations into account (±10 %)

73.18 J needs to be safely absorbed by the NTC thermistor.

2. Use Equation (2) to determine the minimum resistance required by the NTC thermistor:

RMIN = 171.1 V / 30 A

5.70 Ω is required from the NTC thermistor at 25 ºC.

3. Steady-state current:

10 A.

The Ametherm SL22 5R012 is the correct selection for the ambient temperature at 25 ºC.

Rated:

- 5 Ω @ 25 ºC

- 100 J

- 12-A maximum steady-state current

- UL recognized (UL File #: E209153)

- CSA recognized (CSA File #: CA110861)

- RoHS compliant

De-rating of the steady-state current is not necessary because the operating temperature range is not below 0 ºC or above 65 ºC (Fig. 1). De-rating of the resistance is needed since the maximum ambient temperature is 35 ºC. From the Ametherm R/T curve, the coefficient of 35 ºC for de-rating is 0.717.

The minimum resistance needed at 25 ºC will be:

RMIN = Rated resistance at 25 ºC / Coefficient at 35 ºC

RMIN = 5.70 / 0.717

RMIN = 7.94 Ω

The Ametherm MS32 10015 is the correct selection for this example.

Rated:

- 10 Ω @ 25 ºC

- 250 J

- 15-A maximum steady-state current

- UL recognized

- RoHS compliant