Step back for a moment and marvel: In just a few years, we’ve transitioned from no cameras in cars to having multiple ones—an amazing rate of progress. These cameras need multiple voltage rails and thus power-management ICs (PMICs), and the rails must be optimized for the challenging power, size, and operating requirements of the vehicular environment.

Focusing on this well-defined and very large opportunity, the MAX20049 PMIC developed by Maxim Integrated Products squeezes four power regulators—two buck, two LDO—into a total footprint claimed to be the smallest available for this application while also delivering highest competitive efficiency.

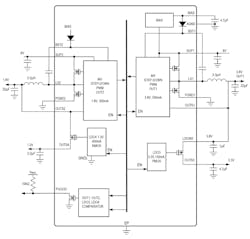

This PMIC (Fig. 1) incorporates two 500-mA step-down (buck) converters and two LDOs (400 mA and 100 mA) in a 3- × 3-mm package with a total function footprint of 38 mm2, compared to 53.3 mm2 for alternative offerings. In addition, it includes features not found elsewhere in this class of product, such as overvoltage protection (OVP), undervoltage lockout (UVLO), external power-good (PG) signal, and cycle-by-cycle current limiting. Best-case efficiency is 74% at full load, greatly reducing the thermal burden.

1.The MAX20049 PMIC from Maxim Integrated Products fits two buck switching converters and two LDOs into a 3- × 3-mm package.

Of course, the input and output voltage specifications are the items of first interest. The two internal, fixed-frequency, pulse-width-modulated (PWM) buck converters operate at input voltages from 5 to 17 V (for the MAX20049) or 4 to 17 V (MAX20049C), compatible with power-over-coax (PoC) that typically uses 8 to 10 V. (There’s also an option of using one of the buck converters as an intermediate supply for generating typical sensor plus serializer rails.) The buck converters are designed to operate 180 deg. out-of-phase with each other to minimize input-current ripple.

Output voltages are factory set and cover the needs of different sensor imagers, including 3.3, 3.0, 2.9, 2.8, or 2.7 V, while the secondary supplies cover the typical 1.8-, 1.2-, 1.1-, and even sub-1.0-V rails for the serializer and memory. The 2.2-MHz switching frequency enables the use of physically small, low-cost ceramic capacitors, and these PMICs feature a spread-spectrum mode option to attenuate EMI and meet CISPR (Comité International Spécial des Perturbations Radioélectriques; in English: International Special Committee on Radio Interference) noise restrictions. The 16-lead MAX20049 comes in a TQFN package with an exposed thermal pad and is AEC-Q100 qualified.

2. Supporting design-in with the MAX20049, the corresponding MAX20049EVKIT# evaluation kit provides standard outputs of 3.8 V, 1.8 V, 3.3 V, and 1.3 V from an input rail up to 17 V.

For design support, Maxim offers EE-Sim models for design and simulation of the MAX20049. In addition, the company offers the MAX20049EVKIT# evaluation kit (Fig. 2), a fully assembled and tested application circuit that provides four output voltages from a single input rail, which can range up to 17 V. It’s pre-populated with the MAX20049ATEA/VY+ version for outputs of 3.8 V, 1.8 V, 3.3 V, and 1.3 V; other MAX20049 options are available.