USB ports are pervasive in automobiles. With the intermediation of the proper cable, numerous portable devices, smartphones, and tablet PCs can be charged on the go. The electronic modules that implement these functions must fit inside small spaces without overheating.

The problem is exacerbated in the case of dual-port dedicated charging solutions (Fig. 1), which must support two connectors without increasing component count and solution size. The dual USB charger must support up to 3 A charging at 5 V per connector, be AEC-Q100-qualified, and comply with Apple and USB specifications. In addition to size and temperature challenges, the solution has to include dual legacy USB enumeration technologies, emit minimal EMI radiation, withstand 40-V load dump, and integrate protection to prevent automotive field returns.

1. Car fitted with dual USB socket.

This design solution reviews the shortcomings of the typical approach and proposes a novel solution to overcome these challenges.

The Heat Problem

The thermal specification of a USB charger module is straightforward—its temperature can’t exceed 40°C above ambient.

Let’s look at a typical solution in which the 5-V charger in a flip-chip package has a junction-to-ambient thermal resistance ΘJ-A = 20°C/W. It draws power from the 14-V car battery, charging a portable device with 6 A at 91% efficiency. The output power is:

POUT = 5 V × 6 A = 30 W

With an efficiency of 91%, the input power is:

PIN = POUT/ η = 30/0.91 = 32.92 W

And the power loss is:

PD = PIN − POUT = 32.92 − 30 = 2.92 W

Accordingly, the temperature rise inside the IC is:

ΔT = ΘJ-A × PD = 20 × 2.92 = 58.4°C

exceeding the specified limit. Clearly the factors at play here are the charger efficiency and its thermal resistance.

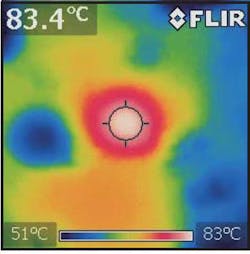

Adding up the ΔT of 58.4°C to the ambient 25°C temperature leads to a peak temperature of 83.4°C (Fig. 2).

2. A typical solution’s peak temperature.

The Size Problem

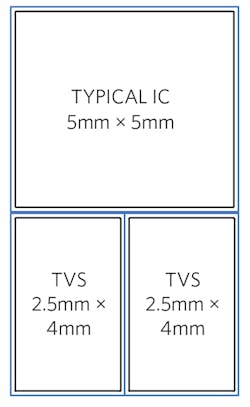

The key to small size is a high level of integration. Figure 3 shows a typical solution that, while integrating the charger control and a powertrain, still requires a couple of external transient voltage suppressors (TVS) to protect from the short to battery and short to VBUS. Accordingly, while the charger IC occupies an area of only 25 mm2, the total active area occupied rises to 45 mm2 once the TVS areas are added.

3. Charger and protection ICs in a typical charger.

When adding the rest of the passives, the PCB side occupancy reaches 333 mm2. Thus, a higher level of integration is necessary to minimize the PCB size.

Highly Integrated Solution

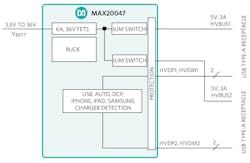

As an example, the MAX20047 (Fig. 4) developed by Maxim Integrated is an automotive-grade, small-footprint dual-port charger IC designed for automotive charging applications. It combines a fully synchronous 6-A step-down buck converter with integrated high-side and low-side FETs that can operate with input voltages from 3.5 to 36V and deliver a 5.2-V output voltage. The IC features integrated iPod/iPhone 1.0-A, iPad 2.1-A, and iPad 2.4-A dedicated charging modes. It also supports an automatic transition between multiple modes such as Apple, USB-IF DCP, China YD/T 1591-2009, and Samsung 1.2 V to enable fast charging on all devices.

4. Shown is a block diagram of the MAX20047 dual-port charger IC.

Short-to-ground protection and overcurrent protection are also provided on the protected HVBUS outputs to protect the internal BUS power rail from an overcurrent fault. The IC offers short-to-battery protection up to +18 V and can be ordered with spread-spectrum operation to reduce EMI. The buck converter’s switching frequency is programmable from 0.4 to 2.2 MHz. The IC is tested to ISO 10605 and IEC 61000-4-2 ESD standards.

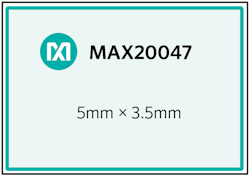

The highly integrated IC integrates the charger and protection in a mere 17.5-mm2 area, almost a third of the previous case (Fig. 5).

5. The MAX20047, with protection integrated, has a small footprint.

When the rest of the passives are included, the total PCB area adds up to only 170 mm2, about half of the previous case discussed.

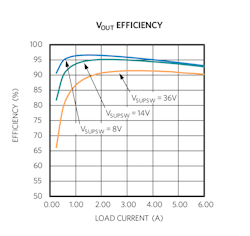

The IC delivers up to 3 A of charging current, displaying high efficiency per port (Fig. 6), through integrated switches with programmable current limit and thermal foldback control. With 93% efficiency at 6 A, the device has a 2% efficiency advantage versus the typical case discussed earlier.

6. Efficiency curve of the MAX20047.

Thermally Enhanced

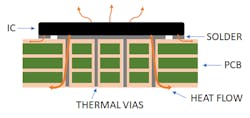

Equally important, the thermally enhanced flip-chip package, in conjunction with an optimized PCB layout, utilizes four-layer 2-oz./2-oz. copper and thermal vias (Fig. 7). This yields a junction-to-ambient thermal resistance (ΘJ-A) of 18°C/W, which is 2°C/W lower than the typical case discussed earlier.

7. Shown is a thermally enhanced PCB employing the charger.

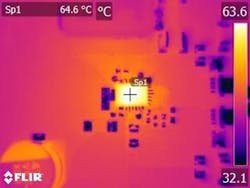

The combined effect of a higher efficiency at 6 A (+2%) and lower thermal resistance (−2°C/W) yields a temperature rise ΔT of only 39.6°C. This temperature rise is 32% lower than the previous case and below the 40°C limit. Adding up the ΔT of 39.6°C to the ambient 25°C temperature leads to a peak temperature of 64.6°C (Fig. 8).

8. The integrated solution reduces peak temperature.

Conclusion

USB ports in automotive charging applications must fit inside small spaces without overheating. The problem is exacerbated in the case of dual-port dedicated charging solutions, which must support two connectors without increasing component count and solution size. We reviewed the shortcoming of a typical solution and showed how a novel automotive-grade, small-footprint dual-port charger IC overcomes the challenges of size and heat generation.

Nazzareno (Reno) Rossetti is a seasoned analog and power management professional and published author, and Adrien Gambino is an applications engineer in the Automotive USB Group at Maxim Integrated.