What you’ll learn:

- The differences between conducted and over-the-air (OTA) testing.

- The hardware building blocks of a conducted RF test environment.

- The measurements to keep in mind when it comes to verification.

From 5G networks and Wi-Fi 7 to the infrastructure underlying the Internet of Things (IoT), the world of wireless connectivity is becoming crowded. In that context, engineers must design everything from the systems-on-chip (SoCs) and chipsets to end devices in such a way that they can operate in these chaotic environments. But verifying RF performance at every stage of the ecosystem is no easy feat.

While over-the-air (OTA) testing has long been industry standard, it looks as though a new test approach is required to keep pace with the shifting market. A more repeatable method—called conductive RF testing—is necessary to efficiently and accurately conduct measurements for the new wireless age. Such a test environment is also poised to provide greater cost efficiencies than traditional radio channel emulators and simulators.

What’s the Difference Between Conducted and OTA Testing?

In OTA testing, the device is verified in a wide range of real-world scenarios to predict its performance and reliability over time. The wireless device is placed inside a test chamber, where these situations can be simulated. The device itself is subjected to different test conditions. By measuring its entire signal path and the performance of the antenna, you can check how the device responds to each scenario.

While OTA testing helps make sure the device will perform the way it was designed to, it may fall short at times. In that context, conductive testing can have more pros than cons compared to OTA testing.

The main differentiator of conducted RF testing is that transmitted and received signals can travel through RF devices, components, and distribution elements during the tests. These components—attenuators, phase shifters, filters, power dividers and combiners, couplers, antennas, coaxial transmission lines, and channel matrices—control and manipulate RF signals inside the test environment. They create a representation of a channel that mimics the way it would work in the field.

A test configuration using RF components also gains an important property of passive RF networks: reciprocity. So, regardless of the direction of signal propagation in the system, the transmission parameters remain the same.

As a result, conductive testing is repeatable, and the conditions that produced a failure can be precisely logged and reproduced. Complex—and sometimes, chaotic—signal environments, including multipath fading and interferers, could be emulated in this type of test environment, too.

Conductive RF Testing: More Than Channel Emulation

Importantly, a conductive environment based on RF hardware can be agnostic to the underlying baseband technology and support analysis of multiple wireless standards such as 3G, 4G, and 5G.

These test systems are also able to assess wireless devices that have multiple channels, such as 4x4 MIMO Wi-Fi and cellular base stations with as many as 96 channels. Such flexibility and adaptability are a boon, as wireless connectivity expands into virtually every electronic device that isn’t connected yet.

Several test scenarios that tend to be performed by a channel emulator can be moved into a conducted test environment. These test environments may include multipath fading models and the emulation of specific MIMO channel conditions. By implementing the test environment with actual RF hardware, it’s possible to realize cost savings. As the amount of MIMO channels in systems rises, these savings can prove to be significant. It may also significantly reduce minimum path delay.

Another important difference is that a channel emulator regenerates the signal, while a conductive environment directly conducts it. This means that the RF interface between a base station and a wireless device can be directly characterized, without the signal characteristics being inadvertently improved by the regeneration.

The Core Building Blocks of Conductive RF Testing

The correct hardware building blocks must be selected to recreate the environment the device will experience.

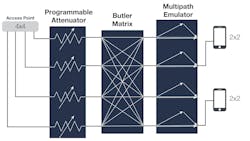

The figure shows a simple test setup for characterizing the throughput of a Wi-Fi device in a conductive environment. Traffic is sent from the base station to the end device and vice versa. The attenuator is varied to characterize the device’s performance in different conditions. An analogous setup could be created for cellular or any other wireless communication standard.

The multichannel programmable attenuator is used to vary the path loss of the emulated channel. It’s crucial to select an attenuator with sufficient dynamic range to make sure the device under test (DUT) will see path losses across the expected range of operation. For Wi-Fi and 5G testing, 95 dB tends to be sufficient. In some cases, however, dynamic ranges of over 120 dB are needed.

A Butler matrix is a device in which each input connects to each output, and the relative phase shift between each port is 180/n, where n is the number of ports. Intuitively, this phase shift replicates the physical spacing between the antennas that would be present in an OTA MIMO channel. Unused ports can be terminated, allowing for a dissimilar number of physical channels to be connected.

Moreover, the device is passive and reciprocal. Several base stations can be connected to a single Butler matrix for modeling of a handover between base stations.

Emulating Multipath

Multipath is a phenomenon where a signal can travel directly between a transmitter and a receiver, or it can reflect off an object and be delayed. At the RF level, this can create a pattern of destructive, as well as constructive, interference.

The impact of multipath indoors—and in some cases, even outdoors—can be emulated using RF hardware. Compared to a standard channel emulator, this approach can present cost savings and reduced insertion delay. This approach also has some downsides, as the supported channel models are fixed at system build and are time invariant.

It may be required to insert fixed attenuators into a conductive test setup. High-power fixed attenuators are needed to reduce the output power from a cellular base station. This avoids damage to the equipment further down the signal path. Fixed attenuators that operate at lesser power levels may be needed to reduce the power received by connected devices to such a level so as to not saturate the receivers.

The Most Important Measurements in RF Testing

A certain level of customization is involved with conductive test systems, as testing a smartphone or other mobile device isn’t the same as testing the 5G cellular base stations and other networking equipment to which they’re connected. But regardless of the application, key measurements need to be performed:

- Throughput: The throughput of multiple wireless devices must be tested at various transmit and receive power levels. Test systems must support many wireless technologies, such as 5G, LTE, Bluetooth, and Zigbee, to verify the performance of modern devices.

- Handover testing: A key measurement, handover testing determines the effective transfer of signals between base stations and devices to ensure transmissions aren’t dropped.

Handover testing is a prime example of the effectiveness of a conductive test system using RF components. The radios under test are connected to power dividers/combiners, then to multichannel programmable attenuators. Finally, the signal is then routed to several devices.

Motion can be emulated by ramping the attenuators to introduce signal loss vs. time. It’s possible to accurately control the ramping rate to mimic typical velocity of mobile devices traveling in vehicles.

Ultimately, no two wireless networks are alike, which poses a problem for electronics engineers, since devices can be used in a variety of scenarios and connect to several different wireless networks at a time. For instance, there are growing private networks for IoT use cases that create significant design and verification challenges.

A conductive test environment is one way to solve these challenges. It gives you the ability to verify performance of end devices, base stations, and chips in diverse environments. Devices in a conductive test environment can mimic a variety of nodes or impairments in a network, resulting in more accurate testing and greater design confidence.