Members can download this article in PDF format.

What you’ll learn:

- What is the PV-Pushback-Effect?

- How can solar day lamps (SDLs) take advantage of this effect?

Solar day lamps (SDLs) are made by simply connecting an LED array to a solar photovoltaic (PV) panel. SDLs represent a highly cost-effective way of utilizing solar energy for lighting. However, SDLs suffer from drawbacks such as daytime-only lighting, light-intensity fluctuations based on sunlight intensity, and low output on cloudy or rainy days.

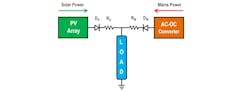

To eliminate those drawbacks, a simple mains backup system is proposed. Figure 1 shows the block diagram of solar lighting system using the PV-Pushback-Effect. It consists of a load (here, it’s an SDL) that’s fed from two sources. The first source is the solar PV power and the second source is mains power with an AC-DC converter. Before connecting these two power sources, a diode and resistor are connected in series with their respective output terminals. The diodes DS and DM ensure that the current from the other source is blocked.

What is the PV-Pushback-Effect?

To understand the PV-Pushback-Effect, we must first look at the PV voltage characteristics, as the load resistance is varied. A simple test was carried out using a PV array with three panels connected in series. The load resistance was directly connected to the output terminals of PV array. Specifications of the PV panels include:

- Solar PV panel power rating: 10 Wp

- Voltage at maximum power (Vmp): 17.5 V

- Open circuit voltage of the panel (Voc): 21.2 V

- Current at maximum power (Imp): 0.58 A

- Number of series connected PV panels in the array: 3

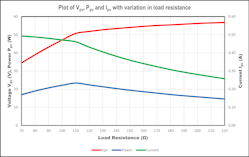

Figure 2 shows the plots of array parameters Vpv, Ppv, and Ipv when the load resistance was varied from 70 to 220 Ω under constant sunlight intensity. The plot of Ppv clearly shows that the maximum power was generated at 110 Ω. The maximum power point is a function of sunlight intensity and the operating temperature of the panels.

The array voltage Vpv keeps on rising as the resistance is increased (initial slope is higher, beyond max power point, the slope is less). This monotonic increase in the array voltage implies that the array is acting as current source. It builds up the voltage until it’s able to force current through the load. If the load is open-circuited, Vpv reaches the open-circuit rating of the array (63.6 V).

This behavior of the PV panels is used to push back the power coming from AC-DC converter. If the PV power increases, the PV voltage pushes back the power coming from the converter. Whenever there’s a reduction in PV power, more power is automatically drawn from the mains. Thus, the user will always get constant light output irrespective of fluctuations in the sunlight intensity.

At any given time, any available PV power is fully utilized to drive the SDL. Only balance power is drawn from the mains supply.

Solar Lighting System Design

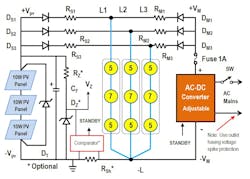

Figure 3 presents a circuit diagram of the proposed solar lighting system. It consists of three PV panels connected in series. The output of the PV array is connected to three LED lamps (L1, L2, and L3) through diodes DS1, DS2, and DS3 and resistors RS1, RS2, and RS3. LED lamps are also connected to the output of AC-DC converter VM through diodes DM1, DM2, and DM3 and resistors RM1, RM2, and RM3.

Design details of the circuit include:

- Solar PV array voltage at maximum power (Vpvm): 17.5 × 3 = 52.5 V

- Forward voltage of 1 W white LED (VLED): 3 V; for 17 LEDs, it’s 51 V

- Number of LEDs connected in series: 52.5/3 = 17.5 (rounded to 17)

- LED current: 0.2 A (max LED current is 0.33 A)

- Number of LED lamps connected to the PV array: 0.58/0.2 = 2.9 (rounded to 3)

- Residual voltage: 52.5 – 51 = 1.5 V; wire resistance from panel to lamp = 0.6 Ω

- Resistance (Rs) = (1.5 V – Vd – Vwire)/0.2 = (1.5 – 0.7 – 0.6 × 0.58)/0.2 = 2.2 Ω

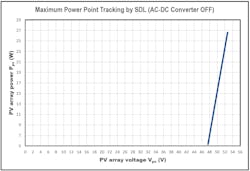

Figure 4 shows the plot of array power Ppv vs. array voltage Vpv. Looking at the plot, it’s very clear that this simple SDL does track the maximum power point very closely. Therefore, an SDL provides a good amount of light throughout the day on a sunny day. If this much light is sufficient, then the AC-DC converter could be manually turned OFF using switch SW.

Selecting the AC-DC Converter

For lamp voltage of 51 V, a 48-V AC-DC converter is selected. This converter has provisions for adjusting the output voltage VM up to 53 V. The converter output is also connected to the lamps (L1, L2, and L3) through diodes DM1, DM2, and DM3 and resistors RM1, RM2, and RM3. These resistors help in increasing the source resistance of the converter.

With these resistors, we can enhance the pushback effect. The output voltage adjustment of the converter also helps in controlling the pushback effect. After a few trials, a 3.3-Ω resistor was selected for each lamp, and VM was set to 52 V. For safety purposes, a 1-A fuse is included in the converter output circuit.

Testing the System

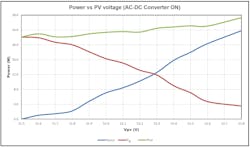

Testing was done at various sunlight intensities. For any given sunlight intensity, Vpv, Ipv, VM, IM, etc., are measured. Figure 5 shows the variation of PV power (Ppvon), converter power (PM), and total power (Ptot) with the converter ON.

At Vpv = 51.5 V, the sunlight intensity is very low. The converter’s power dominates, contributing 100% to the total power output. As the sunlight intensity increases, the PV power builds up and the converter’s power output is reduced to that extent. Total power remains fairly constant. Thus, the user gets constant light output.

Note that at Vpv = 51.5, the maximum power drawn from the converter is about 22 W. This is just an initial setting. If required, it can be increased by boosting the converter output voltage. As we move toward higher Vpv voltage, the total power goes up somewhat due to more power coming from the PV.

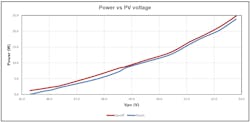

When readings were taken for the converter in Figure 5, at the same time and at the same sunlight intensity (in quick succession), another set of readings were taken with the converter OFF. To study the behavior of the PV array, Ppvon and Ppvoff were plotted in Figure 6.

Note that when the converter is turned ON, the variation in Vpv is restricted to a narrow range from 51.5 to 52.8 V. When the converter is turned OFF, the Vpv range is much wider, from 45.4 to 52.8 V. Ppvoff is plotted with its corresponding Vpv range of 45.4 to 52.8 V. The Ppvon plot from Figure 5 is replotted in Figure 6, against the Vpv range of 45.4 to 52.8 V, for the sake of comparison only.

The plots clearly reveal that when the converter is OFF, PV power is slightly higher. As discussed earlier, the SDL itself follows maximum power point. Hence, when we turn the converter ON, maximum power point gets disturbed due to a change in Vpv. Therefore, about a 1-W reduction in power output from the PV panels is observed when the converter is turned ON.

Resistive Load Testing

Lamps L1, L2 and L3 in Figure 3 were replaced with three 265-Ω resistors. The resistive loads don’t track the maximum power point. However, when the converter is turned ON, the operating point of the PV panels moves nearer to the maximum power point.

It was observed that with the converter ON, we get an extra 10% to 15% PV power output. Thus, if the proposed circuit is used for loads that don’t track maximum power point, we get some extra power from the PV.

Component Selection

The proposed circuit uses just diodes and resistors (instead of complex switching power circuits) to control power coming from mains supply. It’s necessary to minimize losses in these components.

Even though current in each of the diodes is less than 1 A, a high-current-rated diode type 6A10 has been selected. These 6-A diodes have lower forward voltage at lower currents. A Schottky diode will have much smaller forward voltage. However, Schottky diodes aren’t available in high peak-inverse-voltage (PIV) ratings. The diode 6A10 has a PIV of 1,000 V. The AC-DC converter is connected to a mains supply; from there, high-voltage transients can enter the circuit. Hence, use of high PIV diodes is recommended.

If the forward voltage drop of the selected diode isn’t acceptable, then a MOSFET-based polarity reversal protection circuit can be used. Such circuits have negligible forward voltage drop.

Moreover, on the PV side, during lightning, high-voltage transients may enter the circuit. Usually, solar panels come with built-in transient voltage protection. It’s recommended to have a 100-V TVS diode DT across the output terminals of the PV array on the panel. An electrolytic capacitor of 4,700 µF/100 V is connected at the output of PV array. This will smooth out sudden variations in PV voltage.

Checking Out Standby Mode

On a sunny day, if there’s steady and sufficient light output from the SDL itself, then the user can manually turn OFF the AC-DC converter to save power. However, if the sunlight is changing throughout the day, then the AC-DC converter must always be kept ON.

Even on partially cloudy days, there are intermittent spells of bright sunshine. Under such conditions, it’s possible to put the AC-DC converter in Standby Mode. By putting the converter in Standby mode, current drawn will be negligibly small. Whenever the sunlight intensity reduces, the converter will instantaneously come out of standby mode and provide sufficient light from mains power.

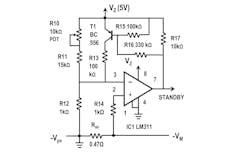

In Figure 3, components shown with * marks are employed to generate the Standby signal. Current-sensing resistor Rsh is used to sense the PV current. When PV current exceeds a threshold value (user-settable), the Standby signal (comparator output) goes high. This signal is connected to the converter, which then goes into Standby Mode. Components Rz (3.3 kΩ, 2 W) and Dz (Zener 5.1 V, 1 W) are used to generate the 5-V power supply (Vz) for the comparator.

Figure 7 shows the circuit diagram of the comparator. It consists of comparator IC1 (LM311). The reference voltage is connected to the inverting terminal Pin 3 using R10, R11 and R12. This reference voltage is user-settable with the help of potentiometer R10. Pin 3 also gets current from resistor R13, which is controlled by PNP transistor T1 (BC556). The non-inverting terminal Pin 2 is connected to the current-sensing resistor Rsh.

When the drop across Rsh exceeds reference voltage at Pin 3, the Standby signal goes high. In addition, T1 turns OFF and the reference voltage drops, thus introducing hysteresis. The T1 and R13 circuit is required because, in this case, the current signal must be connected to the non-inverting terminal. Therefore, this terminal can’t be used to introduce hysteresis, as is usually the case.

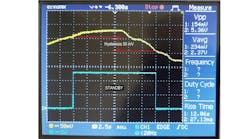

Figure 8 shows the capture of PV current (yellow) and Standby signal (blue). A 50-mV hysteresis is generated, which translates to about 106 mA of PV current. When the Standby signal is high, it will not become low unless the PV current reduces by 106 mA. This will diminish the unwanted chattering of the Standby signal.

Construction of the System

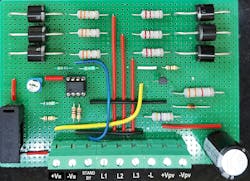

Figure 9 shows the assembled PCB as per the circuit diagram in Figure 3. It includes the PV-Pushback circuit as well as the Standby signal generator circuit. Interconnections to this PCB are available on the 9-pin terminal strip. The power supply from the converter is connected through a fuse for safety.

In Figure 10, the PCB and the AC-DC converter are mounted on same baseplate.

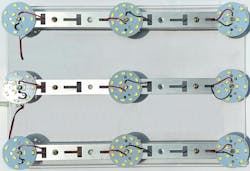

Figure 11 shows the lamps L1, L2 and L3 mounted on a baseplate. Each lamp is made using three metal-core PCBs having white LEDs. Two round PCBs have five LEDs each and the middle round PCB has seven LEDs. Overall, each lamp has 17 LEDs.

Figure 12 illustrates the lamps turned ON, and Figure 13 shows the complete system.

Conclusions

All PV panels demonstrate the Pushback Effect. This effect can be used to mix DC power coming from another source such as a converter or a battery etc. In this article, one example of LED lamp load is presented, but we can extend this to other types of loads, such as heater loads, fan loads, mobile and small two-wheeler chargers, etc. It eliminates all of the drawbacks of pure solar PV systems.

Even though we’re using a backup supply, the power drawn will be optimized based on the sunlight conditions. Users will not notice the transition from daytime to nighttime. It also offers users the opportunity to turn OFF the backup supply if it’s a sunny day. On days with varying sunlight conditions, we can automatically put the converter in Standby mode to save power in converter.

Office buildings, homes, hotels, etc., should have a few of these types of systems. They will save power and work as emergency lamps in the daytime during power failures. If a battery-based system is designed, then it can provide light during nighttime, too, if the grid has failed.

To summarize, a very simple, low-cost lighting system is proposed that doesn’t use any complex switching circuits. It offers reliable day and night operation without user intervention, while providing maximum utilization of solar energy in all seasons. It will prove useful for variety of loads.